Key Takeaways

- A “Trailer Brake Module Fault” in an F-150 indicates a malfunction in the electronic system responsible for controlling the trailer’s brakes, which can compromise towing safety.

- Common causes include wiring issues, corroded connectors, faulty brake controllers, or software glitches in the brake module.

- Symptoms to watch for include dashboard error messages, unresponsive or irregular trailer braking, and persistent error codes after repairs.

- Effective fixes involve inspecting and repairing wiring, cleaning or replacing corroded connectors, resetting or updating the brake module, and replacing faulty components if necessary.

- Regular maintenance, protecting wiring and connectors from corrosion, and updating software as needed help prevent future trailer brake module faults.

If you’ve ever hit the road with a trailer in tow, you know how crucial it is to have reliable brakes. For those of us driving an F-150, seeing a “trailer brake module fault” message pop up can be frustrating and even a little nerve-wracking. It’s one of those issues that seems to appear out of nowhere, leaving us wondering what went wrong.

This fault isn’t just an inconvenience—it can impact the safety of our towing experience. Whether we’re hauling a camper for a weekend getaway or transporting heavy loads for work, understanding what causes this error and how to fix it is key. Let’s dive into what this message means, why it happens, and how we can get back on the road with confidence.

What Is A Trailer Brake Module Fault In An F150?

A trailer brake module fault in an F-150 indicates a malfunction in the electronic module responsible for controlling a trailer’s braking system. This warning typically appears on the dashboard and disrupts the communication between the truck and trailer braking components.

Key Functions of the Trailer Brake Module

- Brake Signal Transmission: Sends the braking signal from the F-150’s system to the trailer brakes.

- Dynamic Adjustments: Manages braking force based on trailer weight and road conditions.

- Error Monitoring: Detects and alerts issues within the trailer braking system.

When this module encounters a fault, either the braking performance of the trailer becomes unreliable, or the brakes may not respond at all.

Common Signs Of A Faulty Trailer Brake Module

Recognizing the signs of a faulty trailer brake module in an F-150 is essential for ensuring safe towing. Below are the most common indicators to watch for.

Warning Messages On The Dashboard

A “trailer brake module fault” message often appears on the instrument panel cluster (IPC). This warning highlights a communication problem between the truck and the trailer braking system. Additionally, fast-blinking turn signals can act as an indirect sign of this fault.

Trailer Brakes Not Functioning Properly

Trailer brakes may stop working altogether even when the truck’s lights and signals seem functional. This lack of braking power poses a considerable safety concern when towing.

Irregular Braking Response

Erratic trailer brake control often results in inconsistent or unreliable braking. In severe cases, the trailer brakes may fail to respond or activate unpredictably, increasing the risk of accidents.

Causes Of A Trailer Brake Module Fault

Understanding the causes of a trailer brake module fault in an F-150 helps address the issue effectively. Several factors can disrupt the communication between the truck and the trailer’s braking system.

Wiring Issues

Damaged or shorted trailer wiring frequently leads to faults in the trailer brake module. Frayed wires or shorts interfere with the signals sent between the truck and the trailer. For example, worn insulation on trailer wires can result in exposed conductors, increasing the risk of electrical faults.

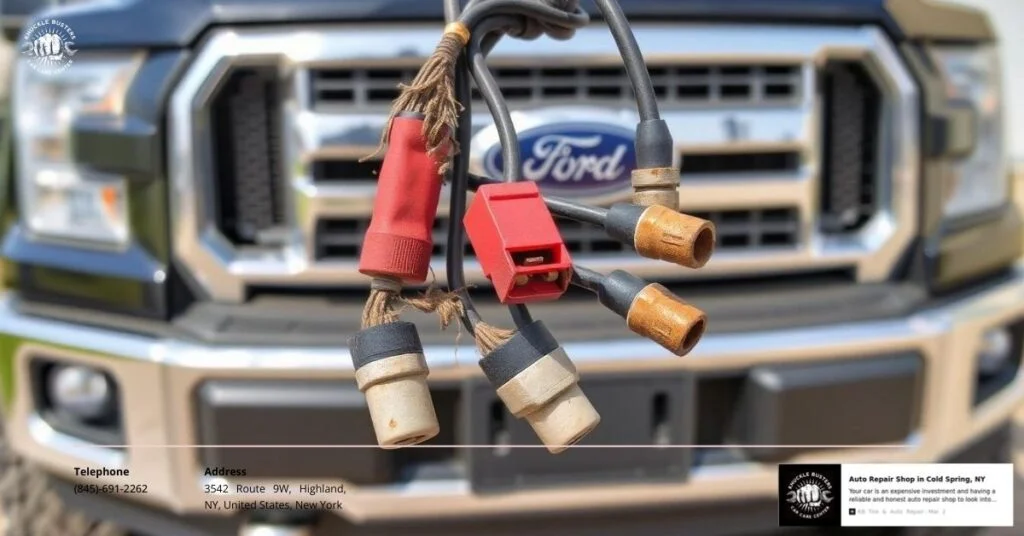

Connector Corrosion

Corrosion on connector plugs or pins disrupts the connection between the trailer and truck. This corrosion increases electrical resistance, causing communication errors with the brake module. Exposure to moisture or road salt, especially during winter, often contributes to this issue.

Faulty Trailer Brake Controller

Overloading the trailer brake controller due to a trailer wiring short circuit can cause internal failures. These failures lead to erratic or non-functional brake control. For instance, a blown component within the controller might prevent it from sending consistent braking signals.

Software Glitches

Glitches in the trailer brake module’s software occasionally trigger fault messages. These glitches can hinder the smooth transmission of critical signals. Ensuring the software is up to date minimizes such errors, as manufacturers release updates to fix known bugs.

Tools And Materials Needed

To diagnose and address a “Trailer Brake Module Fault” in an F-150, having the correct tools and materials ensures accuracy and efficiency during the repair process.

Tools

- Digital Multimeter: For checking electrical continuity, resistance, and voltage in the trailer wiring and module connections.

- Socket Wrench Set: To access and remove faulty components, such as the trailer brake controller or any affected fuses.

- Wire Crimping Tool: Essential for repairing or securing damaged trailer wiring connections.

- Screwdriver Set: Useful for loosening connectors and accessing panels.

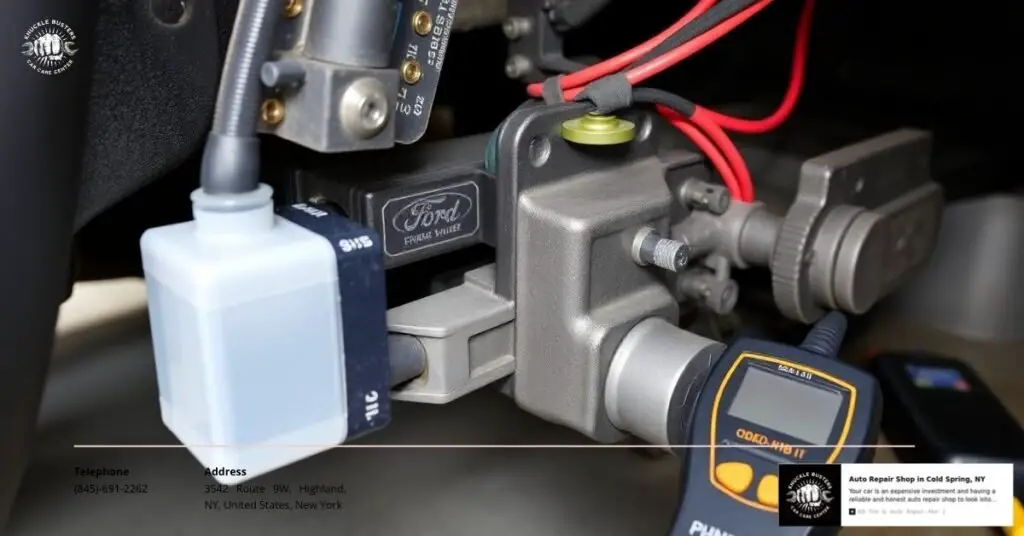

- Handheld OBD-II Scanner: To retrieve diagnostic trouble codes (DTCs) relevant to the trailer brake system.

Materials

- Replacement Fuse (9991): Necessary for restoring power to the trailer tow light module if the original fuse is blown.

- Electrical Contact Cleaner: Helps remove corrosion from connectors and ensure proper electrical contact.

- Heat Shrink Tubing: Protects repaired wiring from environmental damage and enhances durability.

- Dielectric Grease: Prevents future corrosion on cleaned or repaired connectors.

- Replacement Trailer Brake Controller: Required if the current brake controller is faulty.

With these tools and materials, addressing a trailer brake module fault becomes a more manageable process.

How To Diagnose A Trailer Brake Module Fault In An F150

Diagnosing a trailer brake module fault helps ensure safe and reliable towing. Precise checks and tests identify the root cause of the issue.

Checking The Dashboard For Error Codes

Look for a “Trailer Brake Module Fault” message on the dashboard. Specific Diagnostic Trouble Codes (DTCs), such as B1D08:11 or B1D09:11, often accompany this message and are stored in the trailer module (TRM). These codes point to faults in the trailer brake system and may appear even when no trailer is connected. Use an OBD-II scanner to retrieve these codes and confirm the issue.

Inspecting The Wiring And Connections

Examine the electrical system for visible faults. Start by checking fuse number 9991, which powers the trailer tow light module. A blown fuse interrupts power flow and prevents communication between the truck and trailer. Next, inspect the trailer tow connector, particularly connector C4099. Signs of corrosion or damage here, such as rusted pins or frayed wires, increase resistance and disrupt signal transmission. Ensure all connections are clean and securely attached to restore proper functionality.

Testing The Trailer Brake Controller

Verify the functionality of the trailer brake controller. Use a multimeter to measure power output at the controller. A working controller provides consistent voltage when the brake pedal is pressed. Check the controller’s wiring for damage or loose connections. If voltage readings are inconsistent or wiring appears compromised, replace the controller to restore effective braking signals.

Step-By-Step Guide To Fixing A Trailer Brake Module Fault

Fixing a trailer brake module fault in an F-150 involves addressing common causes like wiring issues, corroded connectors, or module malfunctions. Follow these detailed steps to resolve the issue and ensure safe towing.

Step 1: Disconnect The Battery

Disconnect the 12-volt vehicle battery to reset the system. Allow at least 5-20 minutes for stored error codes or temporary glitches to clear before reconnecting the battery. This step can often resolve minor faults without additional measures.

Step 2: Inspect And Repair Wiring

Check the trailer wiring for visible damage, such as frayed or shorted wires. Examine all connections to confirm they are secure and intact. Damaged wiring may overload the brake controller and disrupt communication. For example, replace wires with breaks or exposed sections, and secure loose connections to prevent faults.

Step 3: Clean Or Replace Corroded Connectors

Inspect connector plugs and pins for corrosion that could interfere with electrical signals. Use electrical contact cleaner to remove buildup and apply dielectric grease to protect against future corrosion. Replace heavily corroded connectors to restore reliable communication between the vehicle and trailer.

Step 4: Reset Or Reprogram The Controller

Use a handheld OBD-II scanner to reset or reprogram the trailer brake controller after completing other repairs. Refer to the vehicle’s manual for programming instructions or consult a certified technician if advanced calibration is necessary. Resetting the controller ensures all systems are properly aligned and functional.

Step 5: Replace The Faulty Module (If Necessary)

Replace the trailer brake module if persistent issues remain after completing the previous steps. Obtain a compatible module for the F-150 and follow the manufacturer’s installation procedure. Proper replacement ensures reliable performance and prevents recurring faults during towing.

Troubleshooting Common Issues With A Trailer Brake Module

Resolving a “Trailer Brake Module Fault” in an F-150 sometimes requires addressing persistent or recurring issues. Below are steps to handle specific problems related to the trailer brake system.

Error Codes Still Display After Repairs

Check the trailer brake controller for improper calibration or outdated software if the error code persists. Using an OBD-II scanner, verify that all error codes are cleared after the repair processes. In cases where the fault message continues, inspect the fuse for the trailer brake light module (fuse number 9991) to ensure it is functional. Confirm that all connections, especially around the brake master cylinder, are secure and free from damage.

Trailer Brakes Not Engaging

Inspect trailer wiring for short circuits if the trailer brakes fail to activate. Damaged wiring often disrupts brake signal transmission, leading to unresponsive brakes. Test the functionality of the trailer brake controller to ensure the system is sending the appropriate braking signals. Clean the plug connectors with electrical contact cleaner to remove corrosion, which can block communication between the truck and trailer.

Brake Module Keeps Disconnecting

Secure the connector on the brake master cylinder if the trailer brake module keeps disconnecting during operation. Loose or poorly seated connectors can interrupt the module’s communication with the braking system. Apply dielectric grease to connector plugs to reduce resistance and prevent data loss caused by corrosion. When modules repeatedly fail to stay connected despite these fixes, replacing the trailer brake module may resolve the issue.

Preventing Future Trailer Brake Module Faults

Preventing trailer brake module faults in an F-150 enhances safety and reliability when towing. Consistent maintenance and proactive measures reduce the risk of faults and improve the overall performance of the trailer braking system.

Regular Inspection And Maintenance

Regularly inspect the trailer wiring for visible damage to avoid signal disruptions. Look for signs of fraying, short circuits, or wear, especially at connection points. Ensure all wires are securely connected and show no damage.

Check fuses associated with the trailer tow system, such as fuse number 9991, to ensure proper functionality. Replace them immediately if damaged. Inspect the trailer brake controller for physical damage or irregular behavior. Testing the brake controller during routine maintenance helps identify potential issues early.

Protecting Connectors From Corrosion

Protecting connectors from corrosion ensures uninterrupted signal transmission. Clean connectors using an electrical contact cleaner to remove debris or residue. Apply dielectric grease to connector surfaces to prevent moisture ingress and reduce wear.

Inspect connectors, including those on the brake master cylinder, to identify and address corrosion. Replace heavily corroded connectors with new ones to maintain reliable electrical performance.

Updating Software As Needed

Updating software on the trailer brake module resolves potential glitches and improves communication. Use an OBD-II scanner to check for available updates and reprogram the module, if required.

Stay informed about manufacturer updates or recalls related to the F-150 trailer brake system. Apply the updates promptly to prevent system malfunctions and enhance compatibility with the truck’s features.

Conclusion

Towing safely with our F-150s means staying proactive about potential issues like trailer brake module faults. By understanding the causes, signs, and solutions, we can address problems quickly and keep our vehicles and trailers performing at their best. Regular maintenance and preventive care go a long way in avoiding future headaches and ensuring every trip is as smooth as possible. Let’s prioritize safety and reliability so we can enjoy worry-free towing adventures.

Frequently Asked Questions

What does a “trailer brake module fault” mean in an F-150?

A “trailer brake module fault” indicates a malfunction in the electronic module that manages the trailer’s braking system. This fault disrupts communication between your truck and the trailer brakes, leading to unreliable braking or a lack of response.

What are the common signs of a trailer brake module fault?

Signs include a fault message on the dashboard, irregular or inconsistent trailer braking, fast-blinking turn signals, or the trailer brakes not working properly even when the truck’s lights and signals are functional.

What causes a trailer brake module fault in an F-150?

The primary causes include damaged or shorted wiring, corroded connectors, faulty trailer brake controllers, and software glitches. These issues interfere with communication between the truck and trailer.

How can I fix a “trailer brake module fault”?

To fix this issue, inspect and repair damaged wiring, clean corroded connectors, replace faulty brake controllers, and reset or reprogram the system using an OBD-II scanner. It’s vital to follow a structured troubleshooting process.

What tools do I need to diagnose and repair this fault?

You will need a digital multimeter, socket wrench set, wire crimping tool, screwdriver set, electrical contact cleaner, heat shrink tubing, and an OBD-II scanner.

Can I prevent trailer brake module faults?

Yes, regular inspection and maintenance of trailer wiring, connectors, and brake controllers can help prevent faults. Clean connectors, use dielectric grease, and update module software to avoid common issues.

How do I know if my trailer brake controller is faulty?

If the controller is faulty, you may notice inconsistent braking responses, a lack of braking when towing, or dashboard fault codes. Test the controller or consider replacing it if needed.

Why is my dashboard showing a fault message even after fixing the wiring?

Persistent fault messages may result from a need to reset or reprogram the trailer brake system. Use an OBD-II scanner to clear codes and ensure proper configuration.

Is it safe to tow with a trailer brake module fault?

No, towing with a trailer brake module fault can compromise braking performance and increase the risk of accidents. It’s essential to address the issue immediately before towing.

How often should I inspect my trailer braking system?

Regular inspections are recommended before any towing trip. Additionally, schedule a comprehensive check at least once a year to ensure the overall system is functioning properly.