Wondering where all those tires go on an 18-wheeler? Understanding a semi truck tire position diagram isn’t just for mechanics—it’s essential knowledge for fleet managers, owner-operators and anyone responsible for commercial vehicle maintenance.

When you know the proper positioning of each tire on your big rig, you’ll maximize tire life, optimize fuel efficiency, and enhance safety on the road. Each position serves a specific purpose, from the steering axles that guide your truck to the drive axles that power it forward and the trailer axles that support your load.

In this guide, we’ll break down the complete semi truck tire position diagram, explain why proper tire placement matters, and provide you with the knowledge you need to maintain your truck’s performance and compliance with safety regulations.

Understanding Semi Truck Tire Position Diagrams

Semi truck tire position diagrams serve as essential visual guides that illustrate the specific location of each tire on commercial vehicles. These diagrams use standardized numbering systems to identify every tire position, creating a universal language for drivers, mechanics, and fleet managers.

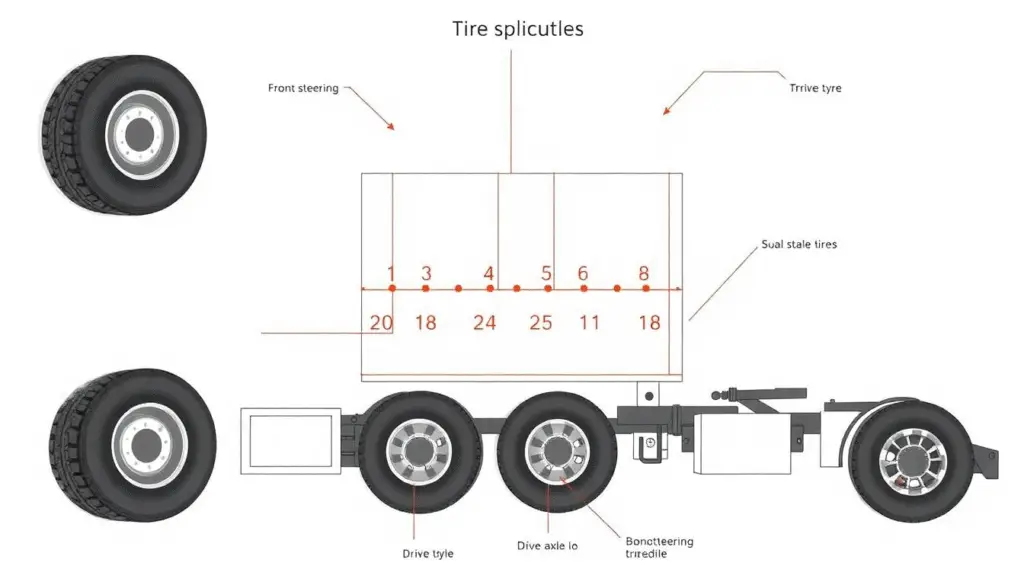

Standard Tire Position Numbering System

The standard numbering system for semi truck tires follows a logical pattern. Position 1 represents the front left steering tire, while position 2 indicates the front right steering tire. Positions 3-6 typically represent drive axle tires, with odd numbers (3, 5) on the left side and even numbers (4, 6) on the right side. Positions 7-10 designate the trailer tires following the same odd-left, even-right pattern.

Reading a Semi Truck Tire Position Diagram

Reading a semi truck tire position diagram involves understanding both the numbering system and the visual layout. Most diagrams display the truck from a top-down view, with the front of the vehicle at the top. Each wheel position is clearly marked with its corresponding number, allowing for quick identification. Dual wheel assemblies are shown as paired circles, while steering tires appear as single circles at the front.

Importance of Correct Tire Positioning

Correct tire positioning directly impacts vehicle performance and safety. Steer tires require specific tread patterns designed for precise handling and wet traction. Drive tires feature aggressive tread designs to maximize traction under load. Trailer tires are engineered for minimal rolling resistance to improve fuel economy. Placing the wrong tire type in any position compromises these specialized functions and creates unnecessary safety risks.

Different Types of Semi Truck Tire Position Diagrams

Semi truck tire position diagrams vary based on truck configuration. Standard 18-wheelers use a 5-axle diagram showing positions 1-10. Super single setups replace dual wheel assemblies with wider single tires, changing the diagram structure. Specialized configurations like tandem trailers or multi-axle heavy haulers use extended diagrams with additional position numbers to account for the extra tires.

Using Tire Position Diagrams for Maintenance Records

Tire position diagrams streamline maintenance documentation by providing a standardized reference point. When recording tire pressure, tread depth, or replacement dates, the position numbers eliminate confusion about which tire is being serviced. This systematic approach creates comprehensive maintenance records that track each tire’s performance throughout its service life, enabling data-driven decisions about rotation schedules and replacement timing.

The Importance of Proper Tire Positioning on Commercial Trucks

Proper tire positioning on commercial trucks directly impacts safety, performance, and operational costs. Semi truck tire position diagrams serve as essential guides to ensure each tire is mounted in its optimal location. When tires are correctly positioned according to the manufacturer’s specifications, you’ll experience improved handling, reduced wear patterns, and enhanced fuel economy.

Incorrect tire placement creates safety hazards including compromised traction, uneven weight distribution, and increased blowout risks. For example, placing a steer-specific tire in a drive position leads to irregular wear and potential handling issues. Studies from the Technology & Maintenance Council (TMC) show that proper tire positioning can extend tire life by up to 20% and improve fuel efficiency by 2-3%.

The financial implications are substantial – commercial fleets operating with correctly positioned tires save thousands in annual maintenance costs. A typical 18-wheeler running 100,000 miles annually can reduce tire replacement expenses by $3,000-$5,000 through proper positioning. Additionally, correctly positioned tires create less rolling resistance, reducing fuel consumption by approximately 0.5 gallons per 100 miles.

Beyond economics, regulatory compliance depends on proper tire positioning. DOT inspections include verification that appropriate tire types are used in their designated positions. Violations can result in costly fines, out-of-service orders, and CSA score penalties. Maintaining precise adherence to semi truck tire position diagrams helps your fleet avoid these regulatory pitfalls while maximizing tire investment and ensuring optimal vehicle performance.

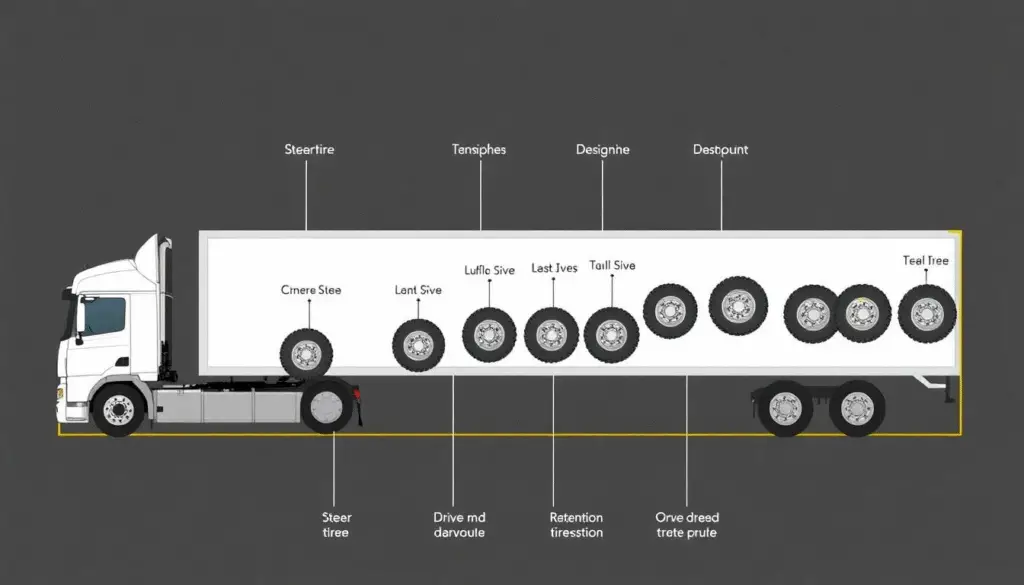

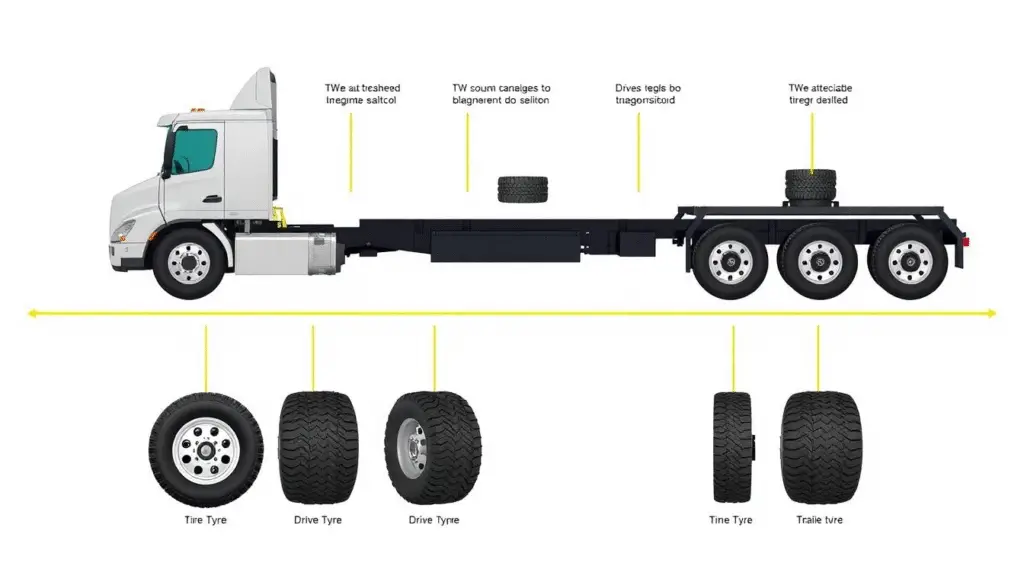

Standard Semi Truck Tire Configuration

Standard semi truck tire configurations follow consistent patterns that enable efficient maintenance and replacement. The semi truck tire position diagram typically divides tire locations into three primary sections: steer axle, drive axle, and trailer axle positions. Each position serves a specific purpose in the truck’s overall performance and safety profile.

Steer Axle Positions

Steer axle tires occupy positions 1 and 2 on the semi truck tire position diagram. These front tires are responsible for steering control and directional stability of the entire vehicle. Steer position tires feature specific tread patterns designed for precise handling and typically have deeper, more robust shoulder ribs to withstand the lateral forces encountered during turning maneuvers. These tires must maintain proper inflation levels between 110-120 PSI to ensure optimal steering response and even wear patterns. Most commercial trucks use single tires at each steer position rather than dual configurations found elsewhere on the vehicle.

Drive Axle Positions

Drive axle positions include numbers 3 through 10 on standard semi truck tire position diagrams. These tires transmit engine power to the road surface and provide the primary traction for the vehicle. Drive positions typically feature dual tire configurations (two tires side-by-side) on each end of the axle, creating an 8-tire arrangement across two axles in standard configurations. The inner tires occupy odd-numbered positions (3, 5, 7, 9) while outer tires take even-numbered positions (4, 6, 8, 10). Drive position tires have aggressive tread patterns with deep lugs designed for maximum traction in various conditions. These tires handle significant torque loads and typically require inflation pressures between 95-105 PSI depending on load ratings.

Trailer Axle Positions

Trailer axle positions comprise numbers 11 through 18 on the semi truck tire position diagram. These tires support the cargo weight and maintain stability of the trailer section. Like drive positions, trailer positions utilize dual tire configurations with inner tires assigned odd numbers (11, 13, 15, 17) and outer tires assigned even numbers (12, 14, 16, 18). Trailer position tires typically feature less aggressive tread patterns than drive tires, with designs focused on wear resistance and low rolling resistance to improve fuel economy. These tires operate under consistent load conditions and generally maintain inflation pressures between 100-110 PSI. Some specialized applications may use super single tires in place of duals at trailer positions to reduce weight and improve fuel efficiency.

Reading and Interpreting Semi Truck Tire Position Diagrams

Semi truck tire position diagrams use standardized visual representations that allow quick identification of each tire’s location on commercial vehicles. Understanding these diagrams is essential for proper maintenance, replacement, and troubleshooting of tire-related issues on heavy-duty trucks.

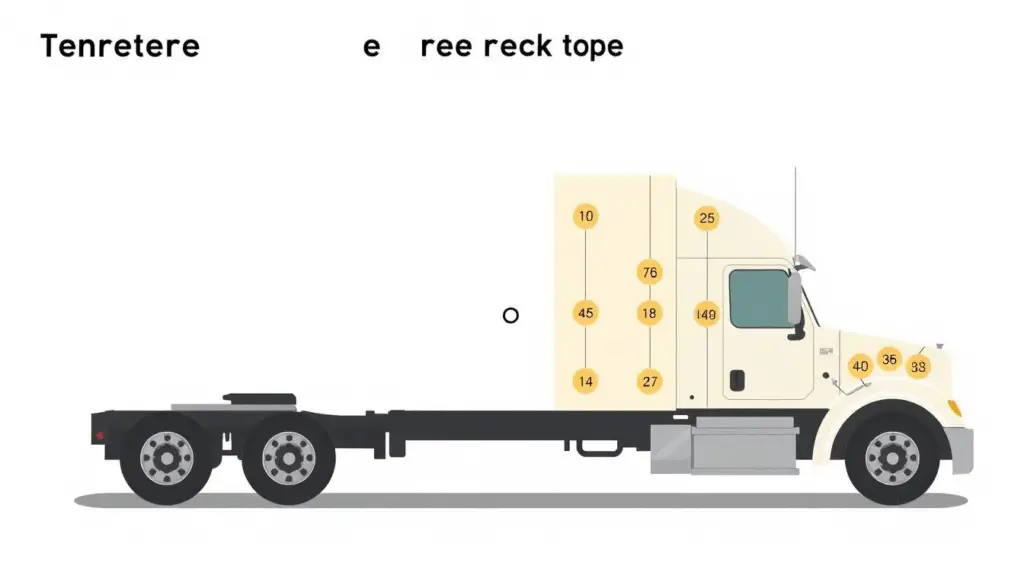

Industry Standard Numbering Systems

The tire position numbering system on semi trucks follows a logical pattern that’s consistent across the trucking industry. This standardization helps mechanics, drivers, and fleet managers communicate effectively about specific tire locations. Most semi truck tire position diagrams start with position 1 at the front right (passenger side) steering tire and position 2 at the front left (driver side). The numbering then progresses rearward through the drive axles (positions 3-10) and finally to the trailer tires (positions 11-18).

For conventional 18-wheelers, the numbering follows this pattern:

| Axle Type | Position Numbers | Location |

|---|---|---|

| Steer Axle | 1-2 | Front of truck |

| Drive Axles | 3-10 | Middle section (tractor) |

| Trailer Axles | 11-18 | Rear section (trailer) |

Some fleets use additional notations like “RS” (right steer) or “LDO” (left drive outside) to further clarify positions. These systems maintain consistency across different truck configurations, including those with super single tires instead of dual assemblies.

Position Codes and Their Meanings

Position codes on semi truck tire position diagrams contain valuable information beyond just location numbers. These codes often include prefixes or suffixes that indicate:

- Axle type: “S” for steer, “D” for drive, and “T” for trailer

- Side designation: “R” for right side, “L” for left side

- Mounting position: “I” for inside (for dual assemblies) and “O” for outside

For example, in a standard position code like “RDO” (Right Drive Outside), each letter communicates critical information about the tire’s exact placement. This level of specificity is particularly important when ordering replacement tires or documenting wear patterns.

These codes also correspond to specific performance requirements. Steer position tires (codes containing “S”) require exceptional handling characteristics and resistance to irregular wear. Drive position tires (codes with “D”) need maximum traction and torque transfer capabilities. Trailer position tires (codes with “T”) focus on wear resistance and low rolling resistance for improved fuel economy.

Understanding these position codes lets you quickly reference the semi truck tire position diagram during maintenance activities, ensuring you’re installing the correct tire type in each location. This precision helps maximize tire life, maintain optimal vehicle performance, and ensure compliance with safety regulations.

How Tire Position Affects Performance and Safety

The strategic placement of tires on a semi truck significantly impacts its overall performance and safety on the road. In the semi truck tire position diagram, each location serves a specific purpose that directly influences how the vehicle handles, stops, and performs under various conditions.

Impact on Handling and Stability

Tire positioning directly affects a semi truck’s handling characteristics and overall stability during operation. Steer tires (positions 1-2 in the semi truck tire position diagram) require specific tread patterns and construction to provide responsive steering and directional stability. These positions demand tires with excellent traction and even wear properties to maintain precise control, especially during emergency maneuvers.

Drive axle tires (positions 3-10) significantly impact traction and stability during acceleration. Properly positioned drive tires with appropriate tread designs provide the necessary grip for power transfer to the road surface. Studies show that incorrect tire placement in drive positions can reduce traction by up to 30% in adverse weather conditions.

Trailer tire positions (11-18) contribute to load stability and tracking. Mismatched or improperly positioned trailer tires often lead to wandering, swaying, or fishtailing—particularly dangerous conditions when carrying heavy or high-center-of-gravity loads. Maintaining proper tire position according to the semi truck tire position diagram reduces these risks substantially.

Cross-axle weight distribution also depends on correct tire positioning. Uneven weight distribution from improper tire placement creates handling imbalances that drivers must constantly compensate for, increasing fatigue and decreasing safety margins during long hauls.

Fuel Efficiency Considerations

Tire position plays a crucial role in a semi truck’s fuel economy. Research indicates that proper tire positioning according to the semi truck tire position diagram can improve fuel efficiency by 2-5%. This translates to thousands of dollars in annual savings for a typical long-haul operation.

Rolling resistance varies based on tire position and design. Steer positions require tires with lower rolling resistance to reduce the energy needed to move the vehicle forward. Drive positions benefit from tires engineered with traction-optimized compounds that still maintain reasonable fuel efficiency characteristics.

Trailer positions often utilize low rolling resistance tires specifically designed to minimize drag and improve fuel economy. Super single tires in appropriate trailer positions can further reduce weight and rolling resistance compared to dual tire configurations, improving fuel efficiency by up to 4% in specific applications.

Aerodynamic drag increases with improper tire positioning. When tires aren’t correctly positioned according to the semi truck tire position diagram, the resulting handling issues often lead to driving adjustments that increase wind resistance and fuel consumption. Proper tire positioning helps maintain optimal vehicle alignment, reducing this unnecessary drag.

Tire pressure maintenance requirements also vary by position. Steer tires typically require higher inflation pressures than drive or trailer positions. Following position-specific pressure guidelines ensures optimal fuel efficiency while maintaining the necessary performance characteristics for each wheel position.

Maintenance Scheduling Based on Tire Positions

Effective maintenance scheduling based on tire positions extends the lifespan of your semi truck tires and maximizes your return on investment. Using the semi truck tire position diagram as a reference point allows for systematic tracking and rotation of tires according to their specific wear patterns and usage demands.

Rotation Patterns for Maximum Tire Life

Tire rotation patterns directly correspond to positions identified in your semi truck tire position diagram. Strategic rotation extends tire life by up to 30% by distributing wear evenly across all tires. For standard 18-wheelers, effective rotation typically follows these patterns:

- Cross-axle rotation: Move drive tires (positions 3-6) to opposite sides of the trailer axle (positions 11-14) to counteract uneven wear

- Side-to-side rotation: Swap tires between dual positions (e.g., position 3 with 5) to balance wear from crown road curvature

- Front-to-drive rotation: Transfer steer tires (positions 1-2) to drive positions after 50% wear, as they’ve experienced even wear patterns

Implementing consistent rotation schedules based on mileage intervals—typically every 30,000-50,000 miles for long-haul operations—optimizes tire performance across all positions. Shorter intervals of 15,000-25,000 miles benefit trucks operating in severe conditions or with frequent stop-and-go driving.

When documenting rotations, always reference the position numbers from your semi truck tire position diagram to maintain accurate service records. This documentation creates a comprehensive history that helps predict future wear patterns and optimize replacement schedules.

Common Problems Associated with Incorrect Tire Positioning

Accelerated Uneven Wear Patterns

Improper tire positioning on semi trucks leads to accelerated and uneven wear patterns that significantly reduce tire lifespan. When tires aren’t placed according to the semi truck tire position diagram, they experience stress in ways they weren’t designed to handle. For example, placing a drive tire in a steer position creates scalloped wear patterns due to the incompatible tread design. Data from the Technology & Maintenance Council shows that incorrectly positioned tires wear out up to 30% faster than properly positioned ones. This premature wear doesn’t just affect the misplaced tire but creates a cascading effect throughout the entire tire system.

Compromised Handling and Stability

Tire positioning directly impacts a semi truck’s handling characteristics and stability on the road. Using trailer tires in drive positions reduces traction capabilities, especially in wet or icy conditions. A study by the National Highway Traffic Safety Administration found that improper tire positioning contributed to 9% of truck accidents where tire factors were involved. When examining the semi truck tire position diagram, you’ll notice each position requires specific tire types because they experience different lateral, braking, and acceleration forces. Proper positioning ensures predictable handling responses during emergency maneuvers and maintains stability when carrying heavy or tall loads.

Increased Fuel Consumption

Incorrect tire positioning creates measurable increases in fuel consumption due to heightened rolling resistance. When drive tires with aggressive tread patterns are installed in trailer positions, their deeper treads generate more friction with the road surface. According to the North American Council for Freight Efficiency, this mispositioning can increase fuel consumption by 2-5% across a fleet. For a typical long-haul operation covering 120,000 miles annually, this translates to 600-1,500 additional gallons of diesel consumed. Following the semi truck tire position diagram ensures each tire’s rolling resistance characteristics match their intended function.

Higher Risk of Catastrophic Failures

Catastrophic tire failures occur more frequently when tires are incorrectly positioned. Placing tires rated for trailer service in steer positions creates dangerous scenarios where the tire structure can’t withstand the steering forces and heat buildup. Analysis of roadside tire failures reveals that incorrect positioning increases blowout risk by 37% compared to properly positioned tires. These failures don’t just create expensive roadside repairs but pose serious safety risks to drivers and other motorists. The semi truck tire position diagram serves as a critical safety guide, ensuring tires with appropriate load ratings and structural characteristics are placed in positions where they can perform safely.

Alignment and Suspension System Damage

Improper tire positioning places abnormal stress on alignment and suspension components, leading to premature wear and system failures. For instance, using mismatched tire sizes on drive axles creates uneven loading across suspension components. This imbalance accelerates wear on bearings, tie rods, and air bag systems. Maintenance records from large fleets demonstrate that trucks with consistently incorrect tire positioning require suspension repairs 40% more frequently than those following proper positioning guidelines. These repairs average $3,200-$4,800 per incident, not including downtime costs. Consulting the semi truck tire position diagram during maintenance ensures tire sizing and specifications remain consistent across axle positions.

Regulatory Compliance Issues

DOT inspections regularly check for proper tire positioning as part of safety compliance reviews. Using incorrect tire types in critical positions violates Federal Motor Carrier Safety Regulations (Section 393.75), potentially resulting in vehicles being placed out-of-service and substantial fines. Commercial enforcement data indicates that tire positioning violations resulted in over $14 million in fines across the trucking industry last year. Beyond the financial penalties, these violations appear on a carrier’s safety record, potentially affecting insurance rates and customer confidence. Adhering to the semi truck tire position diagram helps maintain regulatory compliance and avoids these costly consequences.

Conclusion

Understanding your semi truck tire position diagram isn’t just about maintenance—it’s a strategic advantage for your operation. By mastering this system you’ll maximize tire life extend fuel efficiency and significantly reduce operational costs.

Remember that proper tire positioning directly impacts safety and performance while helping you stay compliant with DOT regulations. The standardized numbering system provides a valuable framework for tracking maintenance and making data-driven decisions about your fleet.

Take time to implement position-specific maintenance schedules and rotation patterns. Your attention to these details can extend tire life by up to 30% and prevent the costly problems associated with incorrect positioning.

In the competitive trucking industry these small details make a big difference in your bottom line and safety record.

Frequently Asked Questions

What is a tire position diagram for an 18-wheeler?

A tire position diagram is a visual guide that illustrates the specific location of each tire on a commercial vehicle using a standardized numbering system. It helps mechanics, fleet managers, and owner-operators identify and track individual tire positions for maintenance, rotation, and replacement purposes.

Why is proper tire positioning important for semi trucks?

Proper tire positioning maximizes safety, performance, and cost-efficiency. When tires are correctly positioned, trucks experience improved handling, reduced wear patterns, and enhanced fuel economy (2-3% improvement). Correct positioning can extend tire life by up to 20% and save thousands in annual maintenance costs.

How are tire positions numbered on a standard 18-wheeler?

Tire positions follow a logical pattern: positions 1-2 are steer axle (front) tires, positions 3-10 are drive axle tires (middle section), and positions 11-18 are trailer axle tires (rear). This standardized numbering system creates a universal reference for maintenance records and tire tracking.

What are the different sections of a semi truck tire configuration?

Semi truck tire configurations have three primary sections: steer axle (positions 1-2) for steering control, drive axle (positions 3-10) for traction and power transmission, and trailer axle (positions 11-18) for supporting cargo weight and maintaining trailer stability.

How does tire position affect fuel efficiency?

Tire position significantly impacts fuel efficiency through differences in rolling resistance. Properly positioned tires can improve fuel economy by 2-3%. Steer positions require responsive tires, drive positions need traction-focused tires, and trailer positions benefit from low rolling resistance tires to optimize fuel consumption.

What happens if tires are incorrectly positioned on a semi truck?

Incorrect tire positioning leads to accelerated uneven wear (up to 30% faster wear), compromised handling and stability, increased fuel consumption (2-5% higher), higher risk of blowouts and failures, and potential damage to alignment and suspension systems. It can also result in regulatory violations and fines.

How often should semi truck tires be rotated?

Semi truck tires should be rotated according to a strategic schedule based on their position. Most fleets implement rotations every 30,000-50,000 miles. Proper rotation can extend tire life by up to 30%. Always document rotations using the position numbers from the tire position diagram for accurate service records.

What are super single tires and how do they affect tire positioning?

Super single tires are wide-base tires that replace dual tire setups on some axle positions. They alter the standard tire position diagram by reducing the total number of tires while maintaining the same position numbering system. They can improve fuel efficiency and reduce weight but require specific positioning considerations.

How do steer tire positions differ from drive and trailer positions?

Steer tire positions (1-2) require specialized tread patterns for responsive steering and stability. They experience different wear patterns than drive positions (3-10), which need aggressive traction, and trailer positions (11-18), which focus on wear resistance and fuel economy.

How can fleet managers use tire position diagrams to reduce operational costs?

Fleet managers can use tire position diagrams to streamline maintenance records, implement strategic rotation schedules, ensure proper tire type placement, track tire performance by position, and make data-driven decisions about maintenance and replacement. This systematic approach can reduce costs by thousands of dollars annually.