Smooth shifting and reliable transmission performance are essential for your Peterbilt 579, yet many owners face frustrating transmission issues that can compromise safety and efficiency. When your truck starts slipping out of gear or experiencing rough shifting, it’s not just an inconvenience—it’s a serious safety concern that demands immediate attention.

Despite the Peterbilt 579 being one of the most technologically advanced trucks on the road, transmission problems remain among the most common complaints. From transmission fluid leaks to computer signaling errors, these issues can quickly escalate from minor annoyances to major mechanical failures. Regular maintenance checks and timely fluid changes are your first line of defense against costly repairs and unexpected downtime.

Common Peterbilt Automatic Transmission Problems

Shifting Issues

Peterbilt automatic transmission shifting problems frequently occur in models like the 579. Many drivers experience difficulty when shifting between specific gears, particularly from 9th to 10th gear. You’ll notice this issue when your truck requires speeds above 67 mph and careful throttle management to complete the shift. These inconsistent gear transitions create frustrating driving experiences and potential safety concerns during highway operations.

Gear Slippage

Gear slippage ranks among the most dangerous Peterbilt automatic transmission problems. This occurs when your truck suddenly loses power after starting to move, as if the transmission has popped out of gear. The NHTSA has identified this issue in various Peterbilt models, including the 579, with recall number 24V190000 affecting over 70,500 units. The cause often stems from improperly crimped right-hand gear shifter stalk connectors resulting in communication loss between the shifter and transmission.

Computer Control Failures

Transmission control module problems plague many Peterbilt trucks with automatic transmissions. Your truck’s computer directs when to shift gears and how much power to send to the wheels. When these signals aren’t transmitted correctly, the transmission behaves erratically. Diagnostic testing often reveals electronic control issues rather than mechanical failures, requiring specialized repair from technicians familiar with Peterbilt’s proprietary systems.

Transmission Fluid Leaks

Transmission fluid leaks compromise your Peterbilt’s shifting performance and longevity. Regular inspection reveals early signs of leaking – from small puddles under your parked truck to unexplained transmission fluid level drops. Leaks commonly originate from damaged seals, loose pan gaskets, or cracked fluid lines. Ignoring these leaks leads to inadequate lubrication, overheating, and eventual transmission failure, resulting in expensive repairs and extended downtime.

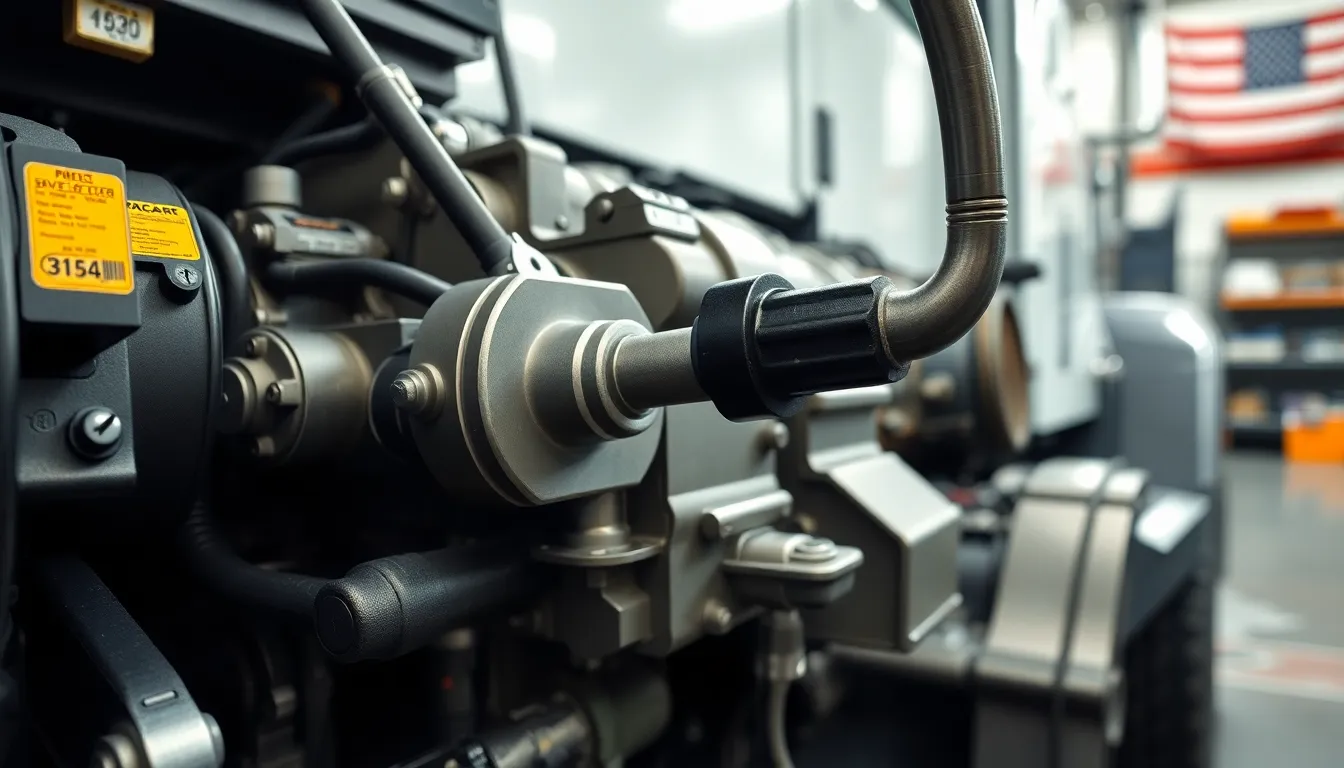

Connector and Wiring Problems

Electrical connection issues frequently cause Peterbilt automatic transmission malfunctions. Failed connectors between the transmission and the Electronic Control Unit (ECU) create intermittent problems that are difficult to diagnose. These electrical problems may cause your transmission to become disabled after stopping, as highlighted in PACCAR’s recent recall affecting 2021-2024 Peterbilt trucks. Regular electrical system inspections help identify corroded terminals or damaged wiring before they cause complete transmission failure.

Signs of Transmission Failure in Peterbilt Trucks

Transmission failure rarely happens without warning signs first appearing in your Peterbilt truck. Recognizing these early indicators can save thousands of dollars in repair costs and prevent dangerous roadside breakdowns.

Grinding or Rattling Noises

Grinding, gurgling, or growling noises from your Peterbilt’s transmission signal trouble ahead. These distinctive sounds typically occur during gear changes or while the truck is in motion. Low transmission fluid often causes these noises, but they may also indicate cracked gears or damaged bearings. Unusual sounds become increasingly pronounced as the transmission problem worsens, and ignoring them leads to catastrophic system failure.

Difficulty Shifting Gears

Shifting problems in Peterbilt trucks manifest as hesitation or resistance when changing gears. Your automatic transmission should shift effortlessly between speeds without grinding, slippage, or shaking. Peterbilt 579 owners commonly report difficulty shifting between 9th and 10th gears, requiring speeds above 67 mph with careful throttle control to complete the shift. Multiple attempts to engage a gear or jerky, rough transitions between gears indicate clogged fluid lines or faulty shift solenoids requiring immediate attention.

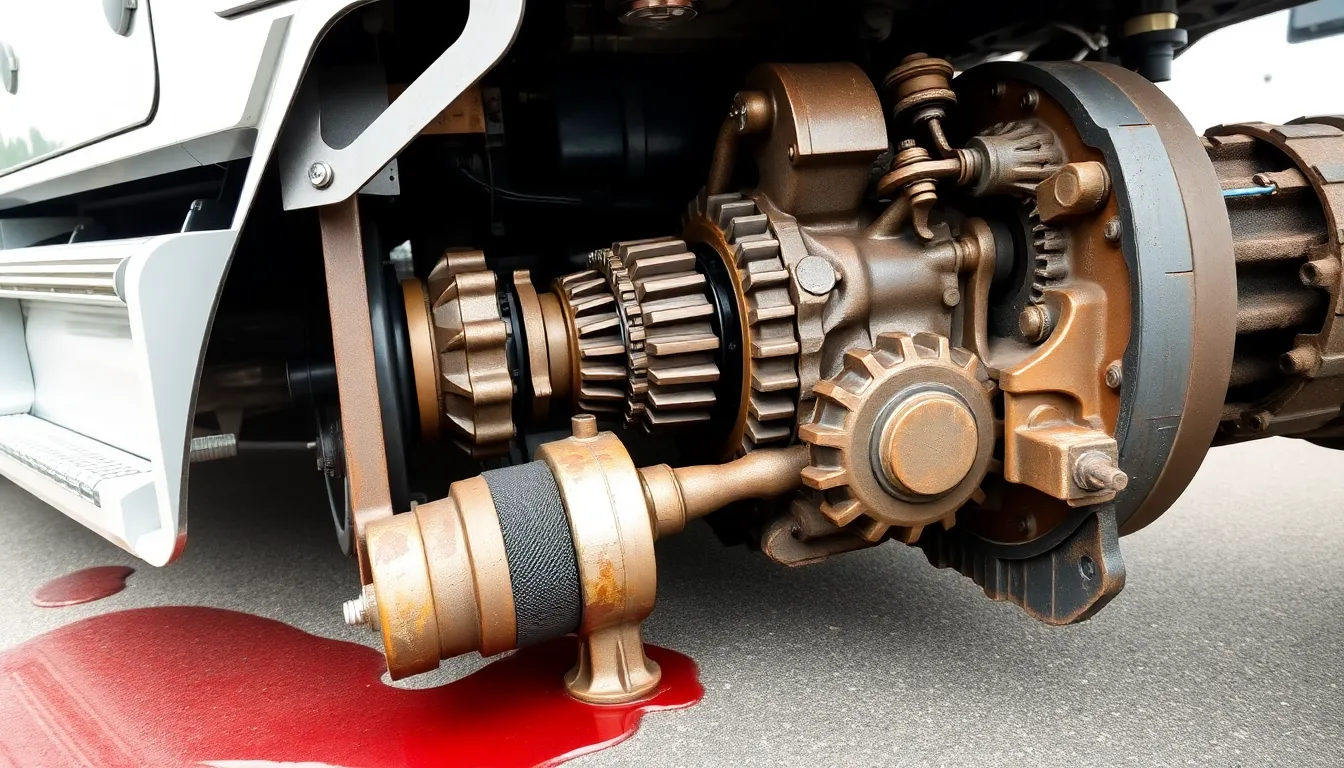

Transmission Fluid Leaks

A reddish fluid puddle beneath your truck is a telltale sign of transmission fluid leakage. This petroleum-smelling fluid lubricates moving parts and prevents excessive wear in your Peterbilt’s transmission. Regular checks underneath your semi before driving help catch leaks early. Left unaddressed, fluid leaks cause component friction, overheating, and eventual transmission seizure. Even small leaks require immediate repair to prevent cascading damage throughout the transmission system.

Burning Smell

A burning odor emanating from your Peterbilt indicates overheated transmission fluid. This distinct smell suggests your transmission is running too hot due to low fluid levels, contaminated fluid, or internal mechanical problems. Overheated fluid loses its lubricating properties, leading to accelerated wear on critical components. The burning smell often precedes more severe symptoms and signals an urgent need for professional diagnosis before permanent damage occurs.

Loss of Power While Accelerating

Sudden power loss during acceleration creates dangerous driving situations for Peterbilt owners. This symptom manifests as the truck starting to move then feeling like it “popped out of gear,” requiring a stop to reset the transmission. Many Peterbilt 579 models have experienced this issue due to improperly crimped gear shifter stalk connectors, leading to communication loss between the shifter and transmission. A recent PACCAR recall affecting over 70,500 trucks addressed this specific automatic transmission problem in 2021-2024 Peterbilt models, highlighting its prevalence.

Specific Issues with Peterbilt Transmission Models

Peterbilt trucks feature various transmission models, each with unique challenges. Understanding these specific problems helps in diagnosing issues before they escalate into major repairs.

PACCAR TX-18 Transmission Problems

The PACCAR TX-18 PRO transmission, available in Peterbilt Models 579, 567, 589, 389, 367, and 365, experiences several recurring issues. Drivers report difficulty with the Off-Road Calibration and Rock-Free Mode features, which sometimes fail to engage properly in challenging terrain. The transmission, designed to handle up to 1850 lb-ft of torque and rated for 140,000 lbs GCWR, sometimes struggles with smooth shifting under heavy loads. Pairing issues between the TX-18 PRO and PACCAR MX11 or MX13 engines can lead to communication errors and unexpected power loss during operation.

Eaton UltraShift Issues

Eaton Cummins Automated Transmission Technologies, including the Endurant series found in many Peterbilt trucks, face specific operational challenges. Drivers often experience high RPM shift points due to improper throttle usage – aggressive pedal application causes the transmission to make aggressive shifts since shift points are controlled by throttle position. Another common issue involves problematic shifting between 9th and 10th gears, requiring speeds above 67 mph and careful throttle modulation to achieve smooth transitions. The automated systems occasionally misinterpret driver inputs, leading to unpredictable shifting patterns and reduced fuel efficiency during normal operation.

Column Shift Mechanism Failures

The right-hand gear shifter stalk in Peterbilt trucks has become a notable problem area, subject to a significant recall affecting 116,343 trucks from model years 2021-2024. The primary issue involves improperly crimped connectors in the shifter stalk, resulting in communication loss between the gear shifter and transmission. This defect manifests as the vehicle becoming disabled after stopping, with the transmission failing to re-engage properly. While only about 4% of affected vehicles are estimated to have this defect, the safety implications are serious as it increases crash risk. The recall affects numerous Peterbilt models including the 348, 365, 367, 389, 535, 536, 537, 548, 567, and 579 series trucks.

Diagnosing Automatic Transmission Problems

Identifying the root cause of Peterbilt automatic transmission problems requires a systematic approach combining observation, testing, and professional expertise. Accurate diagnosis helps prevent costly repairs and keeps your truck operating efficiently on the road.

Using Diagnostic Tools

Electronic diagnostic scanners provide critical insights into Peterbilt automatic transmission problems by reading error codes stored in the transmission control module. Connect an OBD-II scanner to the diagnostic port located under the dashboard to retrieve these codes, which typically start with “P07XX” for transmission-related issues. Advanced diagnostic tools like DAVIE4, Tech Tool, or PACCAR’s proprietary software deliver more detailed transmission data, including shift patterns, fluid temperature, and pressure readings. These measurements reveal hidden problems before they cause complete transmission failure.

Monitor real-time parameters during a test drive to spot irregularities in transmission performance. Pay attention to shift timing, RPM fluctuations between gear changes, and unusual pressure readings. The scanner also records historical data, helping identify intermittent issues that might not appear during a single diagnostic session. For instance, scanning can reveal communication errors between the shifter stalk and transmission that cause gear slippage in the Peterbilt 579’s automatic transmission.

Professional Assessment Methods

Professional technicians employ specialized assessment techniques to diagnose Peterbilt automatic transmission problems beyond what diagnostic tools reveal. A thorough inspection begins with a transmission fluid check – not just level but also color, smell, and particulate content. Dark, burnt-smelling fluid with metal particles indicates internal damage, while pink, frothy fluid suggests coolant contamination. Experienced mechanics perform stall tests to evaluate torque converter function by monitoring RPM changes under controlled conditions.

Road testing provides valuable diagnostic information about transmission behavior under various driving conditions. Technicians evaluate shift quality during acceleration, deceleration, and highway cruising, paying particular attention to the problematic 9th to 10th gear transition in Peterbilt 579 models. They listen for unusual sounds like whining, grinding, or clunking that indicate specific component failures. Pressure testing with specialized gauges measures hydraulic pressure at various ports in the transmission, helping identify failed solenoids, worn pumps, or blocked passages that cause erratic shifting or complete transmission failure.

Repair and Maintenance Solutions

Addressing Peterbilt automatic transmission problems requires both preventative maintenance and timely repairs. Regular attention to your transmission system extends its lifespan and prevents costly downtime that impacts your bottom line.

DIY Troubleshooting Steps

Transmission fluid checks form the foundation of DIY maintenance for Peterbilt automatic transmissions. Check fluid levels weekly, ensuring the truck is on level ground with the engine running at operating temperature. The fluid should appear red or light brown—dark, burnt-smelling fluid indicates contamination requiring immediate attention. Inspect for leaks around transmission seals, pan gaskets, and cooler lines, marking their locations with chalk for easier identification.

Cleaning transmission electrical connections prevents signal transmission errors between your truck’s computer and transmission. Disconnect the battery, locate the transmission control module connectors, and clean them with electrical contact cleaner. This simple procedure often resolves erratic shifting issues in Peterbilt 579 models.

Adjusting shift points through parameter updates can improve performance between problematic gears, particularly the 9th to 10th gear transition that many Peterbilt owners struggle with. Connect a diagnostic scanner to the OBD-II port and check for existing error codes before making any adjustments. Record your current settings before making changes to ensure you can restore them if needed.

Resetting the transmission control module sometimes resolves minor electronic glitches. Disconnect the battery for 15-20 minutes, which forces the system to reestablish baseline settings. After reconnecting, perform a short test drive through all gears to allow the system to recalibrate shift points based on your driving patterns.

When to Seek Professional Help

Grinding noises during gear changes signal internal transmission damage requiring professional assessment. Unlike minor issues, internal component failures typically require transmission removal and specialized equipment for repairs. Continued operation risks complete transmission failure and potential safety hazards.

Persistent slipping between gears, particularly after DIY troubleshooting attempts, indicates more serious problems with clutch packs or valve bodies. Professional technicians use advanced diagnostic equipment to pinpoint the exact cause, often detecting issues before catastrophic failure occurs. For Peterbilt 579 owners experiencing the common 9th to 10th gear shifting problem, specialized diagnostics may be necessary to address programming issues in the transmission control module.

Complete transmission fluid replacement and flushing services should be performed by professionals every 50,000-100,000 miles. This service requires specialized equipment to properly flush all transmission passages, replacing 100% of the fluid instead of the 30-40% typically achieved through DIY drain and fill procedures. Professional flushes remove accumulated metal particles and contaminants that accelerate wear on transmission components.

Major electrical issues affecting the transmission control module often require dealer-level diagnostic tools. Technicians can access manufacturer-specific parameters and perform software updates that address known issues with particular model years. For the Peterbilt automatic transmission problems related to the gear shifter stalk connector recall, authorized service centers have the proper repair procedures and replacement parts to ensure safety compliance.

Preventive Maintenance Tips

Preventing Peterbilt automatic transmission problems requires consistent maintenance and proper operational practices. These proactive measures can significantly extend transmission life and help avoid costly repairs and unexpected downtime.

Regular Fluid Checks and Changes

Transmission fluid serves as the lifeblood of your Peterbilt’s automatic transmission system. Checking fluid levels weekly identifies potential leaks or consumption issues before they escalate into major problems. The fluid should appear clear with a reddish tint—dark, cloudy, or burnt-smelling fluid indicates contamination requiring immediate attention. Follow manufacturer guidelines for changing transmission fluid every 50,000-100,000 miles, depending on your operating conditions. Heavy-duty applications or frequent stop-and-go driving necessitate more frequent changes. Using only transmission fluid specified for your particular Peterbilt model prevents compatibility issues that can damage internal components. During fluid changes, technicians should also replace filters to remove metal particles and other contaminants that accelerate wear on precision components.

Proper Driving Habits

Your driving behavior directly impacts transmission longevity in Peterbilt trucks. Avoid aggressive acceleration, which places excessive strain on transmission components, particularly when hauling heavy loads. Allow your transmission to fully engage before applying substantial throttle—this reduces wear on clutch packs and planetary gear sets. When stopping on inclines, use the parking brake rather than holding position with the accelerator pedal, as this practice overheats transmission fluid and wears out bands and clutches. Refrain from shifting between drive and reverse without coming to a complete stop, which can damage the valve body and cause premature gear failure. Pay special attention when operating between 9th and 10th gears, a common problem area in Peterbilt automatic transmissions. Many drivers have reported difficulty with this particular shift point, especially at highway speeds around 65-67 mph. In cold weather, allow your transmission fluid to warm up adequately before placing heavy demands on the system—cold fluid doesn’t provide proper lubrication and hydraulic pressure, leading to increased wear and potential slipping between gears.

Conclusion

Understanding Peterbilt automatic transmission problems is essential for maintaining your truck’s performance and safety on the road. By recognizing warning signs like unusual noises grinding noises and shifting difficulties you’ll be better equipped to address issues before they escalate into major failures.

Regular maintenance including fluid checks proper driving habits and prompt attention to electrical connection problems can significantly extend your transmission’s lifespan and prevent costly repairs. Don’t ignore symptoms like burning smells or power loss during acceleration as these indicate serious underlying issues.

Whether you’re experiencing challenges with the PACCAR TX-18 PRO Eaton UltraShift or dealing with the recent gear shifter stalk recall professional diagnostics and timely intervention are your best defense against transmission failure and unexpected downtime.

Frequently Asked Questions

What are the common transmission issues in Peterbilt 579 trucks?

Common transmission issues in Peterbilt 579 trucks include shifting problems (particularly between 9th and 10th gear), gear slippage, transmission control module failures, fluid leaks, and electrical connection problems. These issues can cause rough shifting, unexpected loss of power, and erratic transmission behavior that can pose significant safety risks if not addressed promptly.

What causes the shifting problems between 9th and 10th gear?

The shifting problems between 9th and 10th gear in Peterbilt 579 trucks are often caused by faulty sensors, control module issues, or improper fluid levels. This problem is most noticeable at highway speeds and creates frustrating driving experiences. Regular maintenance and professional diagnostics can help identify the root cause and prevent the issue from worsening.

How dangerous is gear slippage in a Peterbilt truck?

Gear slippage in Peterbilt trucks is extremely dangerous as it causes unexpected loss of power, potentially leading to accidents, especially in high-traffic or inclined areas. It’s commonly caused by faulty gear shifter stalk connectors, which has prompted a recall affecting over 116,000 trucks. This issue requires immediate professional attention to ensure driver safety.

What are the early warning signs of transmission failure?

Early warning signs of transmission failure include grinding or rattling noises during gear changes, difficulty shifting gears, transmission fluid leaks, burning smells indicating overheating, and loss of power during acceleration. Recognizing these warning signs early can prevent dangerous breakdowns and save thousands in repair costs.

How often should transmission fluid be changed in a Peterbilt 579?

Transmission fluid in a Peterbilt 579 should be changed every 50,000-100,000 miles, depending on operating conditions. Regular checks are essential – the fluid should appear clear with a reddish tint. Dirty or burnt-smelling fluid indicates it’s time for a change. Proper fluid maintenance significantly extends transmission life and prevents costly repairs.

What is included in the Peterbilt transmission recall?

The Peterbilt transmission recall affects over 116,000 trucks, including models 348, 365, 367, 389, 535, 536, 537, 548, 567, and 579. The recall addresses right-hand gear shifter stalk failures caused by improperly crimped connectors that can disable the vehicle after stopping, increasing crash risk. Affected owners should contact authorized dealers for inspection and repair.

Can I troubleshoot transmission problems myself?

Yes, you can perform basic troubleshooting by checking transmission fluid levels and condition, inspecting for visible leaks, and cleaning electrical connections. However, for persistent issues like grinding noises, gear slipping, or electronic problems, professional help is necessary. DIY maintenance should focus on prevention rather than repairing major failures.

What diagnostic tools are used for transmission problems?

Professional technicians use electronic diagnostic scanners to read error codes from the transmission control module, advanced diagnostic tools to analyze shift patterns and fluid conditions, and perform thorough inspections including road tests. These comprehensive methods help identify specific component failures that may not be apparent through standard diagnostics.

How can I extend the life of my Peterbilt transmission?

Extend your Peterbilt transmission’s life by maintaining proper fluid levels, scheduling regular fluid changes, avoiding aggressive acceleration, using the parking brake on inclines, and allowing the transmission to warm up in cold weather. These preventive measures significantly reduce wear on components and help avoid expensive repairs.

Is it better to repair or replace a failing transmission?

The decision to repair or replace depends on the severity of the issue, the truck’s age, and overall condition. Minor issues like sensor failures or fluid leaks are cost-effective to repair, while extensive internal damage might justify replacement. Consult with a professional technician who can provide a detailed assessment and cost comparison for both options.