Is your Dodge Ram 1500 refusing to start when you turn the key? Starter problems are among the most frustrating issues Ram owners face, often leaving you stranded at the worst possible moments.

When your reliable Ram suddenly develops starting issues, it’s typically related to the starter motor, solenoid, or electrical connections. These components can fail due to age, excessive wear, or exposure to extreme conditions. While some starting problems might seem mysterious, most follow recognizable patterns that can help you diagnose and address the issue before it leaves you calling for a tow.

Common Dodge Ram 1500 Starter Problems

Dodge Ram 1500 trucks experience several recurring starter issues that frustrate owners across different model years. Recognizing these common problems helps you diagnose issues quickly and avoid unnecessary repairs. Let’s examine the most frequent starter-related problems that affect these popular trucks.

Clicking Noise But No Start

A clicking noise when turning the key indicates your Ram 1500’s starter solenoid is captivating, but the motor isn’t turning over. This clicking sound comes from the solenoid attempting to activate the starter motor without success. Electrical current flows to the solenoid, causing it to click, but insufficient power reaches the starter motor itself. Several factors cause this frustrating issue:

- Weak battery connection: Corroded or loose battery terminals prevent adequate current flow

- Depleted battery: Battery voltage drops below 12V, providing insufficient power

- Faulty solenoid: Internal damage prevents proper electrical contact

- Worn starter contacts: Degraded contact points fail to complete the circuit

Liam Kohn recalls a customer who experienced persistent clicking for weeks before discovering a hidden corrosion issue at the battery terminal that wasn’t visible without removing the connection completely.

No Sound When Turning Key

Your Ram 1500 making absolutely no sound when turning the key points to a complete electrical failure in the starting system. This silent symptom typically stems from more serious electrical issues than simple clicking problems. The complete absence of noise suggests electrical current isn’t reaching the starter components at all. Common causes include:

- Dead battery: Complete battery failure provides no power to any starter components

- Ignition switch failure: Damaged switch prevents the starting signal from reaching the starter

- Broken starter relay: Failed relay interrupts the electrical path between ignition and starter

- Severed wiring: Damaged wires disconnect the starter circuit completely

Grinding Noise During Start

Grinding noises during startup indicate mechanical problems with your Ram 1500’s starter components. This harsh metal-on-metal sound occurs when the starter drive gear fails to properly mesh with the engine’s flywheel teeth. The grinding results from improper alignment or damaged components trying to engage. Four primary causes of this damaging sound include:

- Misaligned starter: Improper mounting positions the starter gear incorrectly

- Worn flywheel teeth: Damaged teeth on the flywheel prevent proper engagement

- Damaged starter drive: Broken or worn gear teeth can’t properly mesh with the flywheel

- Bent starter shaft: Deformation prevents smooth engagement of gears

“I’ve seen customers ignore grinding sounds for months,” shares Liam. “By the time they brought their trucks in, they needed both starter and flywheel replacements—doubling their repair costs.”

Starter Stays Engaged After Engine Starts

A starter that remains engaged after your engine starts creates a distinctive whining noise and risks serious damage. This problem occurs when the starter motor continues running after the engine has already started. The starter solenoid fails to disengage the starter gear from the flywheel, causing both to spin simultaneously at different speeds. This dangerous condition stems from:

- Stuck solenoid: Solenoid plunger remains in the engaged position

- Ignition switch malfunction: Failed switch continues sending the start signal

- Jammed starter drive: Mechanical binding prevents the starter gear from retracting

- Electrical short: Wiring problem maintains current to the starter

Intermittent Starting Problems

Intermittent starting issues in Ram 1500 trucks frustrate owners because they’re difficult to diagnose and often appear resolved only to return unexpectedly. These sporadic problems create uncertainty about whether your truck will start each time you turn the key. The unpredictable nature of intermittent issues typically stems from:

- Loose connections: Vibration occasionally disrupts electrical connections

- Heat-sensitive components: Parts that fail only at certain temperatures

- Corroded connectors: Partial corrosion creates inconsistent electrical contact

- Failing ignition switch: Partially damaged switch works unpredictably

One Ram owner told Liam about spending $800 on unnecessary parts before discovering a simple loose ground wire was causing intermittent starting problems for over three months.

Symptoms of a Failing Starter in Your Dodge Ram 1500

Recognizing the warning signs of a failing starter in your Dodge Ram 1500 helps you address problems before you’re left stranded. These symptoms typically appear gradually and become more frequent as the starter deteriorates.

Clicking Sounds When Turning the Key

Clicking noises when you turn your Ram’s ignition key indicate a starter system struggling to function properly. This sound occurs when the starter solenoid attempts to engage but fails to turn the engine over. Your truck’s electrical system may be sending power to the starter, but internal components can’t complete the starting process. Corroded connections or insufficient power delivery to the starter solenoid often cause this symptom. Many Ram owners report that this clicking becomes more pronounced in cold weather or when the battery hasn’t been used for extended periods.

Slow or No Cranking

Engine cranking issues directly point to starter motor problems in your Dodge Ram 1500. When you turn the key and the engine cranks very slowly or doesn’t crank at all, worn internal components within the starter motor are likely the culprit. Electrical issues that reduce power delivery to the starter can mimic this symptom. Checking voltage with a multimeter helps determine if your battery is providing adequate power to the starter system. Damaged brushes or commutators inside the starter motor eventually fail to generate sufficient torque to turn the engine, resulting in sluggish cranking that worsens over time.

Intermittent Starting Issues

Unpredictable starting behavior creates frustration for many Ram 1500 owners. Your truck might start perfectly one moment but refuse to crank the next time you turn the key. These inconsistent starting patterns often connect to a failing starter or faulty ignition switch. Holding the key in the start position for extended periods before the engine finally cranks indicates deteriorating starter components. Heat-sensitive parts within the starter assembly can cause your Ram to start normally when cool but fail when the engine compartment heats up. Loose electrical connections to the starter create intermittent contact, leading to unreliable starting performance even with a fully charged battery. Many Ram owners have temporarily resolved these issues by tapping the starter housing, which momentarily allows stuck components to function before permanent replacement becomes necessary.

Major Causes of Starter Failure in Dodge Ram 1500

Dodge Ram 1500 trucks commonly experience starter failures due to several exact issues. Understanding these core problems helps you diagnose and address starter issues before they leave you stranded.

Electrical Connection Issues

Loose or corroded electrical connections prevent your Ram’s starter motor from receiving the necessary power to engage properly. You’ll notice intermittent starting problems or clicking noises without the engine actually cranking when these issues arise. Corrosion often builds up at battery terminals and ground connections, creating resistance that blocks the high current needed for starter operation. Inspecting and cleaning these connections regularly eliminates many starting problems without requiring expensive parts replacement.

Solenoid Failure

The starter solenoid acts as the crucial link between your ignition switch and the starter motor in your Dodge Ram 1500. When this component fails, you’ll typically hear no crank when turning the key or just a single click sound. Solenoid failures occur from repeated use or exposure to extreme temperatures that damage internal components. Testing the solenoid’s electrical circuit helps determine if it’s the source of your starting troubles, and replacing this component costs significantly less than a complete starter assembly.

Worn Starter Motor Components

Internal components within your Ram’s starter motor wear out over time, particularly the brushes, armature, and drive gear. You’ll identify this issue by grinding noises during start attempts or increasingly inconsistent starting performance. Heat buildup from frequent short trips accelerates wear on these components, as does the stress of starting in extremely cold temperatures. A comprehensive starter motor replacement resolves these issues but requires verifying that other electrical systems like the battery and alternator are functioning properly first.

Battery health directly impacts starter performance, so a weak or dead battery mimics many starter motor symptoms. Similarly, ignition switch problems cause intermittent starting issues that many Ram owners mistakenly attribute to the starter itself. Diagnosing these related components saves unnecessary repairs and expense when troubleshooting your truck’s starting system.

Diagnosing Starter Problems in Your Dodge Ram 1500

Starter problems in the Dodge Ram 1500 typically reveal themselves through distinct symptoms that signal trouble with your truck’s starting system. Recognizing these warning signs early helps prevent unexpected breakdowns and costly repairs. Common indicators include unusual noises when turning the key, intermittent starting issues, or complete failure of the engine to turn over.

Using a Multimeter to Test the Starter

A multimeter serves as an essential diagnostic tool for pinpointing electrical issues in your Ram’s starter system. Testing begins by connecting the multimeter leads directly to the starter terminals while a helper turns the ignition to the start position. The voltage reading should measure close to battery voltage (approximately 12 volts) during cranking attempts. Readings significantly below this value indicate potential problems with wiring, the starter solenoid, or internal starter motor failure. Voltage drop tests can also identify excessive resistance within the starter circuit that impairs necessary current flow. Many Ram owners find that conducting these electrical tests saves hundreds in diagnostic fees at repair shops by confirming whether the starter itself requires replacement or if the issue lies elsewhere in the electrical system.

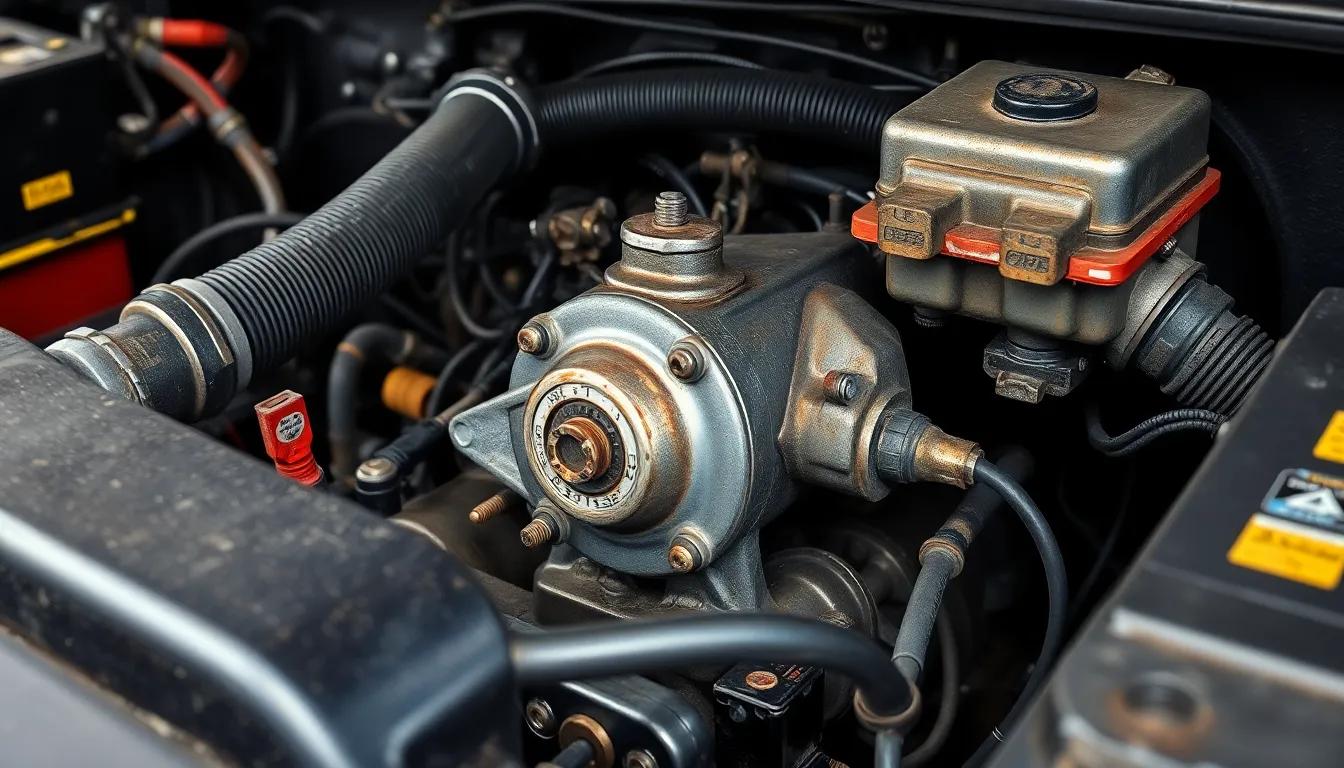

Visual Inspection Techniques

Physical examination of your Ram’s starter components often reveals problems before electrical testing becomes necessary. Begin by thoroughly checking for oil contamination, physical damage, or visible wear on starter gears and components. Inspect all starter mounting bolts to verify the unit remains firmly attached to the engine block. Examine the entire wiring harness and ground connections for corrosion, fraying, or loose connections that could interrupt power flow. Listen carefully during start attempts for telltale sounds – grinding noises typically indicate worn starter gears, while repetitive clicking suggests the starter gear fails to properly engage with the flywheel. Corroded or loose battery terminals frequently cause symptoms that mimic starter failure, so always inspect these connections first. Owners of Ram trucks in coastal or high-humidity regions face accelerated corrosion issues, making regular visual inspections particularly important for maintaining reliable starting performance.

DIY Fixes for Minor Starter Issues

Many Dodge Ram 1500 starter problems can be resolved without professional help using simple DIY techniques. These practical answers address common issues that prevent your truck from starting properly.

Cleaning Battery Connections

Corroded or loose battery terminals restrict electrical flow to your starter, causing frustrating no-start conditions. First, disconnect both battery terminals, starting with the negative cable to prevent electrical shorts. Using a wire brush or terminal cleaner, thoroughly remove any white or greenish corrosion buildup from both the terminals and cable ends. Apply a thin layer of petroleum jelly or commercial battery terminal protectant to prevent future corrosion. Reconnect the cables securely, attaching the positive terminal first, then the negative, and ensure they’re tightened properly for optimal electrical contact. Regular cleaning of battery connections often resolves intermittent starting issues without requiring starter replacement.

Jump Starting Techniques

Jump starting your Ram 1500 provides a temporary solution when your battery lacks sufficient power to engage the starter motor. Position a donor vehicle with a good battery close to your truck, ensuring the vehicles don’t touch. Connect the red jumper cable to the positive terminal on both batteries. Attach the black cable to the negative terminal of the donor battery, then connect the other end to a solid metal ground point on your Ram’s engine block (not the negative battery terminal). Start the donor vehicle and let it run for 3-5 minutes before attempting to start your Ram. Once your truck starts, remove the cables in reverse order, starting with the ground connection. This technique bypasses weak battery issues that mimic starter failures and can help determine if your starter is actually defective or if you’re simply dealing with battery problems.

Starter Motor Tapping

The starter motor’s internal components occasionally stick or bind, preventing normal operation even when receiving adequate power. For this quick troubleshooting technique, locate your starter motor (typically mounted where the engine meets the transmission) and gently tap it with a hammer or wrench while someone turns the ignition key. The light mechanical shock can free stuck solenoid contacts or brushes within the starter assembly. Many Ram 1500 owners report success with this method, particularly with intermittent starting issues that occur when the engine is hot. Remember that this is only a temporary fix – if tapping works repeatedly, your starter likely needs replacement soon.

Testing the Ignition Switch

Faulty ignition switches cause many Ram 1500 starting problems that are mistakenly attributed to the starter motor. Test your ignition switch by turning the key to the “ON” position (before cranking) and checking if dashboard lights illuminate properly. Listen for the fuel pump priming sound that should occur before starting. If these preliminary electrical systems aren’t activating, your ignition switch may be faulty. Replacing the switch costs approximately $50 for parts and can be completed in about an hour using online tutorials. This repair often resolves intermittent starting issues where the truck eventually starts after multiple key turns or holding the key longer than normal.

Checking Safety Interlocks

Your Ram 1500 contains several safety switches that prevent starting when certain conditions aren’t met. Verify that your transmission is fully in Park or Neutral, as a misaligned shifter can prevent starter engagement. Check that the brake pedal switch functions correctly by confirming your brake lights work properly. For trucks with clutch pedals, ensure the clutch safety switch engages completely when the pedal is depressed. Malfunctioning safety interlocks produce symptoms identical to starter failures but are typically easier and less expensive to fix.

When to Replace Your Dodge Ram 1500 Starter

Your Dodge Ram 1500’s starter shows distinct warning signs when it’s approaching failure. Recognizing these indicators early can save you from being stranded and prevent additional damage to related components.

Key Warning Signs

Unusual Noises signal starter problems that shouldn’t be ignored. Clicking sounds typically indicate the starter gear is captivating but failing to turn, while grinding noises suggest worn teeth or improper gear engagement. These distinctive sounds serve as early warning signals that your starter is beginning to fail.

Starting Failure occurs when your engine doesn’t crank even though turning the key. This common symptom directly points to a bad starter motor in many cases. Your truck might also exhibit intermittent starting problems—working fine one moment, then refusing to start the next—which strongly suggests the starter is deteriorating.

Multiple Start Attempts become necessary when your starter is failing. You’ll notice you need to hold the ignition key longer than normal or try starting multiple times before the engine finally cranks. This pattern indicates your starter motor is struggling to perform its basic function.

Continuing to drive with these symptoms risks additional complications. Your battery may drain prematurely from repeated starting attempts, and the excessive wear can damage your engine’s flywheel, leading to more expensive repairs down the road.

Average Replacement Costs

Dodge Ram 1500 starter replacement typically costs between $250 and $600 including both parts and labor. Parts alone range from $100 to $300 depending on the quality and source you choose. Labor costs vary by location and shop rates, typically accounting for 1-2 hours of work.

DIY replacement can save you approximately $150-$250 in labor costs if you have the proper tools and mechanical knowledge. Many Ram owners find this repair manageable with basic automotive tools and a repair manual or online tutorial.

Pricing fluctuates based on your truck’s model year and engine size. The 5.7L Hemi engine, for example, often requires a different starter than the 3.6L V6, which affects overall cost.

OEM vs. Aftermarket Options

OEM starters come directly from Dodge or their authorized manufacturers and match your Ram 1500’s original equipment specifications. These parts typically cost $200-$300 but offer guaranteed compatibility and reliability. Dodge OEM starters usually include a 12-month warranty and maintain the same durability standards as your truck’s original component.

Aftermarket alternatives from brands like Bosch, ACDelco, and NAPA provide cost-effective options ranging from $100-$200. These parts sometimes offer enhanced features like improved solenoid designs or better heat resistance. Premium aftermarket brands often provide longer warranties—sometimes up to 3 years—compared to OEM parts.

Performance differences between OEM and aftermarket options are minimal for most drivers. Aftermarket parts have improved significantly in recent years, though quality varies considerably between economy and premium brands. Your decision eventually depends on your budget constraints and how long you plan to keep your truck.

Many Ram owners report that choosing a mid-tier aftermarket starter from a reputable brand offers the best balance of reliability and value for trucks beyond the warranty period. For newer vehicles, sticking with OEM parts helps maintain resale value and ensures perfect compatibility.

Preventing Future Starter Problems

Regular maintenance prevents many common starter issues in your Dodge Ram 1500. Electrical problems often manifest before complete failure, giving you time to address them before being stranded. Implementing these preventive measures helps extend your starter’s lifespan and ensures reliable performance.

Regular Inspection and Maintenance

Battery connections require frequent inspection for corrosion or looseness. Clean terminals with a wire brush and baking soda solution to remove buildup that restricts electrical flow. Tightening battery cables eliminates resistance that forces your starter to work harder than necessary. Testing your battery, starter, and alternator during routine maintenance appointments catches potential issues before they escalate into major problems.

Addressing Electrical Issues Promptly

Electrical faults cause many Dodge Ram 1500 starter failures. Loose, corroded, or damaged wiring creates resistance in the starting circuit, preventing sufficient current from reaching the starter motor. Ignition switches sometimes fail intermittently rather than completely, resulting in unreliable starts even when both battery and starter test good. Wiring problems, particularly in the ignition system, can become worse after the vehicle heats up during operation, leading to voltage drops and starting difficulties.

Professional Diagnosis When Needed

Intermittent starting problems demand professional attention from a trained mechanic. Electrical issues often mimic starter failure but require different repair approaches. Diagnostic tools identify voltage drops or resistance problems that aren’t visible during visual inspections. Professional testing evaluates the entire starting system, including the battery, starter motor, solenoid, ignition switch, and connecting wires, providing a comprehensive solution rather than temporary fixes.

Conclusion

Addressing your Ram 1500 starter problems doesn’t have to mean an expensive trip to the mechanic. With the right knowledge you can diagnose common issues like clicking noises no-start conditions or grinding sounds and often fix minor problems yourself through simple maintenance steps.

Whether you choose to attempt DIY repairs or seek professional help understanding the warning signs of starter failure can save you from being stranded. Remember that starter issues typically cost between $250-$600 to fix professionally but many problems can be prevented through regular battery and electrical system maintenance.

By staying proactive with your truck’s starter system you’ll extend its reliability and avoid the frustration of unexpected breakdowns. Your Ram deserves proper care and now you have the insights to provide it.

Frequently Asked Questions

What causes a clicking noise but no start in my Dodge Ram 1500?

A clicking noise without starting typically indicates the starter solenoid is activating but the motor isn’t engaging. This is commonly caused by weak battery connections, a depleted battery, faulty solenoid, or worn starter contacts. Check your battery connections first, as this is often the simplest fix before moving on to more complex components.

Why is there no sound when I turn the key in my Ram 1500?

Complete silence when turning the key suggests a serious electrical failure. This is typically due to a dead battery, failed ignition switch, broken starter relay, or damaged wiring. Begin troubleshooting by checking the battery voltage and connections, then work your way through the starting circuit if those check out.

What does a grinding noise during startup indicate?

Grinding noises during startup point to mechanical issues in your Ram 1500’s starting system. Common causes include misalignment between the starter and flywheel, worn flywheel teeth, damaged starter drive gear, or a bent starter shaft. This requires prompt attention as continued use can cause more extensive damage.

Why does my starter stay engaged after the engine starts?

When the starter continues running after engine startup, it’s typically caused by a stuck solenoid, malfunctioning ignition switch, jammed starter drive, or an electrical short. This condition can damage both the starter and the engine’s flywheel if not addressed quickly, requiring immediate attention.

What causes intermittent starting problems in a Dodge Ram 1500?

Intermittent starting issues are often due to loose electrical connections, heat-sensitive components, corroded connectors, or a failing ignition switch. These problems are frustrating because they come and go, making diagnosis challenging. Systematic testing of components when the problem occurs is the best approach.

How can I fix minor starter issues myself?

Many minor starter issues can be resolved with DIY fixes such as cleaning battery terminals, jump-starting the vehicle, tapping the starter motor (which can temporarily free stuck components), testing the ignition switch, and checking safety interlocks. These simple solutions can often get you back on the road without a mechanic.

When should I replace the starter in my Ram 1500?

Replace your starter when you notice persistent unusual noises, frequent starting failures, or need multiple start attempts consistently. Other indicators include burning smells during starting, visible damage to the starter, or if your truck is older with the original starter. Ignoring these signs can lead to being stranded.

How much does a Dodge Ram 1500 starter replacement cost?

Starter replacement for a Dodge Ram 1500 typically costs between $250-$600, depending on whether you choose professional installation or DIY. The part itself ranges from $100-$350, while labor adds $150-$250. DIY replacement can save significant money if you have the necessary tools and mechanical knowledge.

Are OEM or aftermarket starters better for my Ram 1500?

OEM starters offer guaranteed compatibility and reliability but cost more. Aftermarket starters provide cost savings with varying quality levels. Premium aftermarket brands often offer comparable reliability to OEM with better warranties at lower prices. Your choice depends on budget, how long you plan to keep your truck, and your comfort with non-factory parts.

How can I prevent future starter problems?

Prevent starter issues by regularly inspecting battery connections for corrosion, maintaining a healthy battery (replace every 3-5 years), having your electrical system tested during routine maintenance, addressing electrical issues promptly, and being attentive to early warning signs like slower-than-normal cranking or unusual noises during startup.