When it comes to the 68RFE transmission, we all know it’s a workhorse, but even the toughest machines can use a little help. Whether we’re towing heavy loads or pushing for better performance, upgrades can make a world of difference in reliability and efficiency. The right tweaks can transform our 68RFE into a powerhouse that handles whatever we throw at it.

Upgrading isn’t just about fixing issues—it’s about unlocking potential. From improved durability to smoother shifts, there are plenty of ways to take our transmission to the next level. Let’s explore some of the most effective upgrades and how they can keep our trucks running stronger, longer.

Understanding The 68RFE Transmission

The 68RFE transmission, found in many popular heavy-duty vehicles, is known for its balance of power and functionality. However, understanding its limitations is crucial when considering upgrades to maximize its performance.

Common Issues With The 68RFE

Many 68RFE transmissions face recurring issues under heavy loads or extended use. These include torque converter failures, inadequate clutch durability, and overheating. Torque converter failure can manifest as shuddering or slipping. Weak internal clutches may lead to poor shift quality or erratic gear performance. Overheating is a common issue when towing heavy loads, decreasing transmission fluid efficiency and component lifespan.

Benefits Of Upgrading The 68RFE

68RFE upgrades significantly enhance the durability, performance, and capacity of this transmission. Reinforced torque converters prevent slippage, ensuring smoother power delivery under load. Upgraded clutch packs provide consistent shifts and handle higher torque demand. Enhanced cooling systems control fluid temperature, prolonging transmission life during demanding operations. These improvements not only address common wear but also optimize the transmission for towing and heavy-duty applications.

Materials And Tools Needed

Gathering the right materials and tools is critical to successfully complete 68RFE upgrades. Proper preparation ensures smoother installation and avoids delays.

Essential Tools

- Torque Wrench: Use for precise tightening specifications during assembly.

- Socket Set: Include metric and standard sizes for compatibility with 68RFE components.

- Transmission Jack: Provides safe and stable support for removing and reinstalling the transmission.

- Pick Set: Helps remove and install internal seals without causing damage.

- Service Manual: Reference for accurate torque values and assembly details.

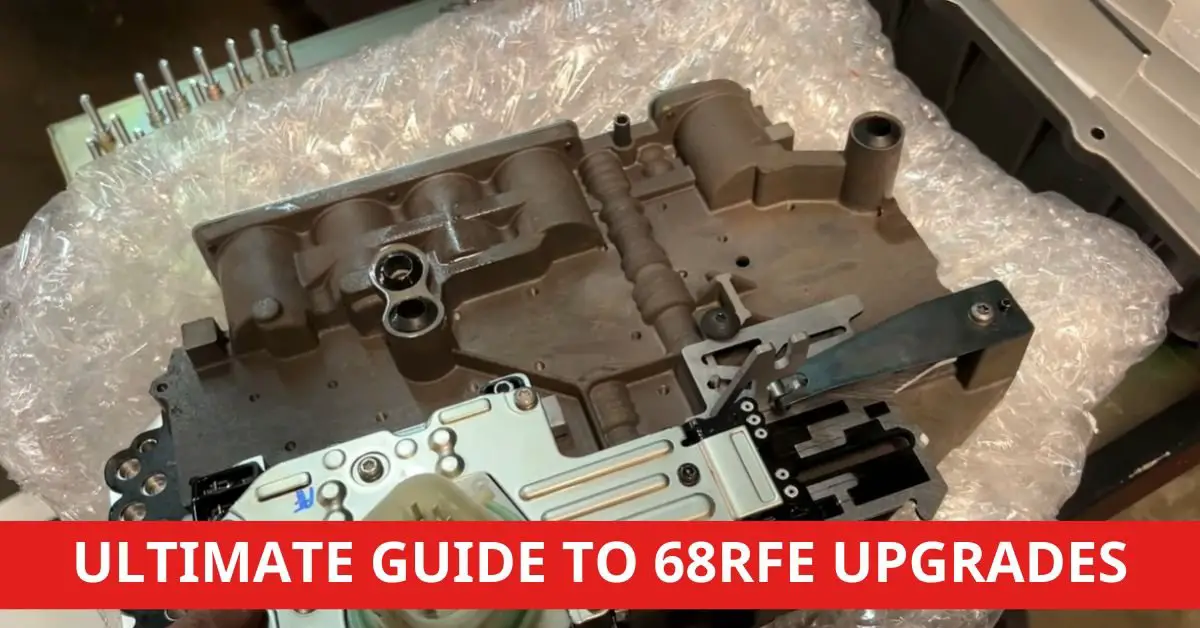

Recommended Upgrade Kits

- Reinforced Torque Converter Kit: Improves towing performance and prevents shuddering under load.

- Upgraded Clutch Pack Kit: Enhances durability to handle heavy-duty applications.

- High-Performance Valve Body Kit: Optimizes hydraulic flow for smoother and faster shifts.

- Transmission Cooling System Kit: Keeps operating temperatures lower, reducing the risk of overheating damage.

- Transmission Fluid: Use manufacturer-recommended fluids for 68RFE to maintain peak performance.

- Seals and Gaskets: Prevent leaks during reassembly with new and durable replacements.

- Cleaning Solvent: Cleans parts efficiently, ensuring debris doesn’t disrupt transmission functions.

- Safety Gear: Use gloves and goggles for personal protection during installation work.

Proper tools and supplies simplify the process and maximize the benefits of 68RFE upgrades.

Planning Your 68RFE Upgrade

Planning ensures an effective approach to maximize the benefits of 68RFE upgrades. Careful consideration of your vehicle’s requirements and resources paves the way for a successful project.

Assessing Your Vehicle’s Needs

Understanding your vehicle’s transmission performance is critical before selecting upgrades. Start by identifying current issues, such as slipping gears, overheating, or delayed shifting. Consider your specific application needs, like towing heavy loads or off-road driving, to determine the exact areas requiring improvement. For example, if overheating occurs routinely, an improved cooling system may be necessary. Use mileage and driving habits to evaluate wear severity and component stress.

Choosing The Right Upgrades

Select components tailored to resolve existing problems and enhance performance. Reinforced torque converters improve power handling for trucks towing large trailers. Upgraded clutch packs increase shift durability under high stress. Performance valve bodies offer smoother shifts and optimized fluid flow. For trucks with overheating issues, installing a high-capacity transmission cooling system ensures temperature regulation during demanding usage. Ensure compatibility by reviewing the specifications of upgrade kits before purchasing.

Setting A Budget

Establishing a budget helps prioritize necessary upgrades while avoiding overspending. Account for essential tools, upgrade kits, and professional labor costs if applicable. For example, high-performance valve bodies may cost $400-$800, while a reinforced torque converter ranges from $800-$1,500. Allocate funds for quality components, as compromising here could undermine long-term performance. Ensure the total budget includes extra expenses, such as new seals, gaskets, and transmission fluid.

Step-By-Step Guide To 68RFE Upgrades

Follow these steps to upgrade the 68RFE transmission and enhance its durability and performance. Proper execution of each step ensures optimal results and long-term reliability.

Step 1: Preparing Your Workspace

Create a clean and organized workspace to facilitate a smooth upgrade process. Ensure the area is well-lit and spacious enough for safe transmission removal. Gather all necessary tools, including a torque wrench, socket set, transmission jack, and pick set. Lay out upgrade kits like a reinforced torque converter kit, valve body kit, and clutch pack kit for easy access.

Step 2: Draining The Transmission Fluid

Drain the transmission fluid to reduce mess and make the disassembly process easier. Place a drain pan beneath the transmission, then remove the drain plug or transmission pan bolts to release the fluid. Dispose of the used fluid responsibly per local regulations.

Step 3: Removing The Transmission Pan

Remove the transmission pan to access internal components. Loosen and carefully detach the pan bolts in a cross pattern to prevent warping. Inspect the magnet for metal debris, which may indicate component wear. Thoroughly clean the pan and replace the gasket with a new one to ensure a proper seal during reassembly.

Step 4: Installing An Upgraded Valve Body

Install a high-performance valve body to improve shift quality and pressure regulation. Remove the old valve body by disconnecting electrical connectors and bolts. Replace it with the upgraded unit, ensuring all connections align correctly and bolts are torqued to manufacturer specifications. This step enhances fluid flow and prevents common shifting issues in the 68RFE.

Step 5: Replacing Clutch Packs

Replace clutch packs to improve durability under heavy-duty use. Remove the transmission and access the clutch assembly. Disassemble the unit and replace worn or weak clutches with upgraded packs designed for increased holding power. Reassemble the clutch assembly, ensuring correct alignment and clearances for optimal operation.

Step 6: Reinforcing The Torque Converter

Install a reinforced torque converter to handle higher torque loads and minimize shuddering. Remove the old torque converter from the transmission input shaft and replace it with the upgraded unit. Ensure proper installation by verifying the converter is fully seated and the bolts are secured according to manufacturer guidelines.

Step 7: Adjusting The Transmission Tuning

Perform transmission tuning adjustments to optimize performance after installing the upgrades. Use a tuning tool compatible with the vehicle to recalibrate the transmission control module. Modify shift points, line pressure, and torque converter lockup to synchronize with the upgraded components. This step maximizes the efficiency and functionality of the 68RFE upgrades.

Tips For Enhancing Upgrade Performance

Optimizing 68RFE upgrades requires attention to detail and adopting best practices. Following these tips can enhance the longevity and efficiency of your upgraded transmission.

Selecting High-Quality Components

Using high-quality components is critical for successful 68RFE upgrades. Reinforced torque converters, upgraded clutch packs, and performance valve bodies are examples of reliable parts. Trust reputable manufacturers whose products are tested for durability under heavy loads. Component quality directly impacts performance and reduces the likelihood of premature failures.

Maintaining Proper Fluid Levels

Ensuring the right transmission fluid levels supports optimal performance and protects internal components. Use manufacturer-recommended ATF+4 fluid and check levels regularly. Overfilling can cause foaming, while low levels may lead to overheating. Maintain consistency in fluid quality by replacing it at recommended intervals or after intensive use in heavy-duty applications.

Breaking In Your Upgraded Transmission

Breaking in the upgraded transmission establishes proper function and extends its lifespan. Drive conservatively for the first 500 miles, avoiding aggressive towing or high-speed conditions. This approach allows clutch packs to seat correctly and ensures smooth operation under normal workload pressures.

Troubleshooting Common Issues

When performing 68RFE upgrades, issues may arise that affect transmission performance. These challenges can often be resolved by addressing specific causes.

Overheating After Upgrades

Overheating may persist even after completing 68RFE upgrades. Improper fluid levels or insufficient cooling systems often cause this issue. Check that the transmission fluid reaches the correct level, as too much or too little fluid can disrupt heat dissipation. Inspect the cooling system for blockages or inadequate airflow. Ensure the upgraded transmission cooler is free from debris and properly connected to maintain optimal performance.

Slipping Or Hard Shifting

Slipping gears or hard shifting typically indicates tuning or installation problems. Verify that all components, including the upgraded torque converter and clutch packs, were correctly installed during the 68RFE upgrades. Reprogram the transmission control module to accommodate the new upgrades, as outdated shifting patterns can contribute to poor shift quality. Use a scanner to check for diagnostic trouble codes, which may provide insight into potential electronic or hydraulic issues.

Fluid Leaks Post-Upgrade

Fluid leaks often occur when seals or gaskets are improperly installed after completing 68RFE upgrades. Double-check the installation of new seals and gaskets to ensure a proper fit. Inspect the transmission pan bolts for incorrect torque, as under-tightening or over-tightening can disrupt the seal and lead to leaks. Use a high-quality manufacturer-recommended RTV sealant along with new gaskets to enhance durability and prevent fluid loss.

Alternative Upgrade Methods

Exploring alternative upgrade methods for the 68RFE transmission can help optimize performance while catering to different budgets and expertise levels. Below are key approaches to consider.

Professional Installation Services

Opting for professional installation services guarantees expert handling of 68RFE upgrades. Certified technicians ensure precise installation of components like upgraded clutch packs or reinforced torque converters. They also verify proper tuning and compatibility with the vehicle’s system. This method reduces the likelihood of installation errors and simplifies the process for those without prior experience. Contacting a reputable transmission specialist is crucial for obtaining reliable results tailored to the vehicle’s demands.

DIY Alternatives On A Budget

DIY alternatives can make 68RFE upgrades accessible for individuals with mechanical knowledge. Investing in comprehensive upgrade kits like high-performance valve body kits or improved transmission cooling systems minimizes complexity. Using essential tools such as a torque wrench and transmission jack while following a detailed service manual ensures accurate component replacement. This approach suits those aiming to save costs while enhancing transmission performance, provided installation is performed carefully.

When To Consider A Full Transmission Swap

Considering a full transmission swap may be necessary for severely damaged or worn-out 68RFE units. This option becomes relevant when upgrades cannot sufficiently resolve issues like excessive wear, overheating, or persistent slipping. Replacing the transmission with a factory-refurbished or high-performance 68RFE offers a fresh platform for durability and efficiency. Consultation with transmission experts can help evaluate whether a swap outweighs the benefits of individual upgrades.

Conclusion

Upgrading the 68RFE transmission is a smart investment for anyone looking to enhance their vehicle’s performance and reliability. By addressing common weaknesses and tailoring upgrades to specific needs, we can unlock the full potential of this hardworking transmission.

Whether we choose DIY methods or professional installation, careful planning and quality components are key to long-term success. With the right approach, our 68RFE can handle even the toughest challenges with ease, giving us confidence every time we hit the road.

Related Posts: