Are you experiencing frustrating issues with your 2.8 Duramax engine? While this powerplant offers impressive torque and fuel efficiency, it’s not without its share of common problems that can leave owners scratching their heads.

The 2.8L Duramax diesel engine found in vehicles like the Chevrolet Colorado and GMC Canyon has developed a reputation for certain recurring issues. From DEF system failures and emission control problems to cooling system complications and fuel injector malfunctions, these engines present unique challenges for owners. Understanding these potential trouble spots can help you anticipate problems before they leave you stranded or facing costly repairs.

Understanding the 2.8L Duramax Engine

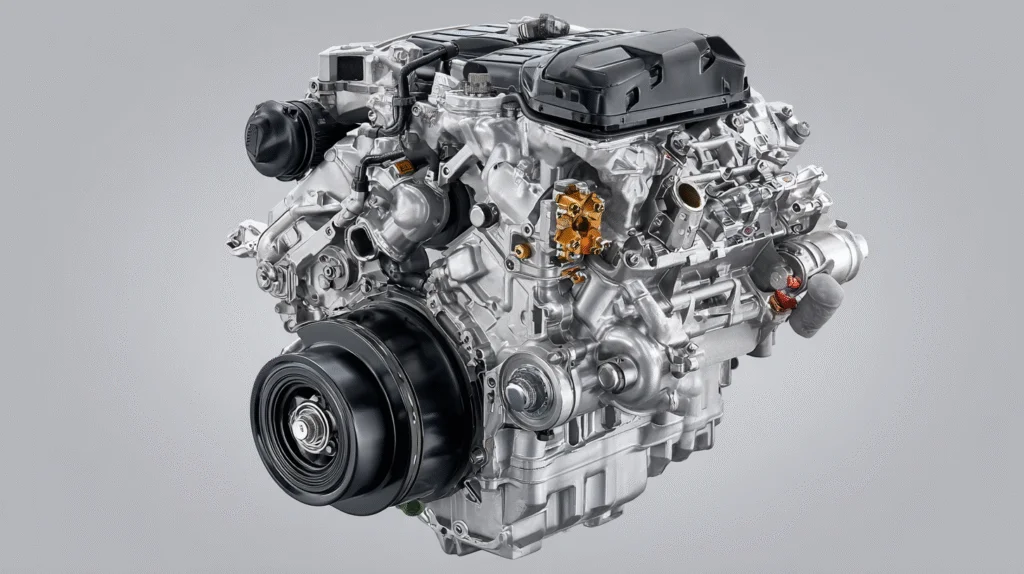

The 2.8L Duramax diesel engine represents GM’s commitment to creating powerful yet efficient smaller displacement diesel options for the North American market. Introduced in 2016, this four-cylinder turbocharged engine quickly gained popularity in the Chevrolet Colorado and GMC Canyon midsize trucks. Its compact design delivers an impressive 181 horsepower and 369 lb-ft of torque while maintaining excellent fuel economy ratings.

GM designed the 2.8L Duramax with several advanced features including a high-pressure common rail fuel system, ceramic glow plugs, and a variable geometry turbocharger. These components work together to optimize performance across different driving conditions. The engine’s cast-iron block provides exceptional durability, while its aluminum DOHC cylinder head helps reduce overall weight.

Owners appreciate the engine’s towing capabilities, which exceed many competitors in its class. The 2.8L Duramax allows properly equipped Colorado and Canyon models to tow up to 7,700 pounds—a important advantage for a midsize truck. This towing capacity comes from the engine’s substantial low-end torque, available from just 2,000 RPM.

Even though its strengths, the 2.8L Duramax has exhibited exact recurring issues. Many problems center around the emissions control systems, particularly the Selective Catalytic Reduction (SCR) system that uses Diesel Exhaust Fluid (DEF). These systems, while necessary to meet strict emissions standards, create additional complexity and potential failure points.

“I’ve seen dozens of customers come in with DEF-related warning messages,” says Liam Kohn, noting that these issues often appear after 50,000-75,000 miles. “The frustration is understandable—they bought these trucks for reliability, and instead they’re facing check engine lights and reduced power modes.”

The engine’s cooling system components have also proven problematic for some owners. Coolant leaks from water pumps and radiators have been reported with concerning frequency. Addressing these cooling system failures promptly is critical, as overheating can cause extensive damage to this diesel engine.

Common Problems With the 2.8L Duramax Engine

The 2.8L Duramax diesel engine found in Chevy Colorado and GMC Canyon trucks suffers from several recurring issues that affect performance and reliability. These problems typically center around three major systems: emissions controls, fuel delivery, and cooling components.

Emissions System Failures

Emissions system failures rank among the most frustrating issues for 2.8L Duramax owners. The engine incorporates multiple emissions control components including a diesel oxidation catalyst, diesel particulate filter (DPF), selective catalyst reduction (SCR), and exhaust gas recirculation (EGR) system. Each component plays a exact role—the EGR reduces combustion temperature by rerouting exhaust gases back into the intake, while the DPF captures soot particles and burns them off during regeneration cycles. Many owners report these systems becoming problematic as their vehicles age, particularly after reaching 50,000-75,000 miles. Performance degradation, reduced power, and check engine lights commonly indicate emissions system issues. Repair costs for these components can be substantial, making them a important concern for long-term ownership.

Fuel System Issues

Fuel system problems frequently plague the 2.8L Duramax, with premature fuel filter clogging being particularly common. This issue triggers reduced engine power warnings and error codes such as P026D and P228C. Symptoms include engine stalling during operation, rough idling, difficulty starting in cold weather, and diminished fuel injector performance. Earlier versions of the LWN Duramax engine experienced issues with fuel injectors sticking open, which often resulted in piston damage. GM addressed these problems with injector updates, but fuel system reliability remains a concern. Regular replacement of the fuel filter and using high-quality diesel fuel can help mitigate these issues, though professional inspection becomes necessary when problems persist.

Cooling System Problems

Cooling system failures create another vulnerability in the 2.8L Duramax engine design. Engine overheating occurs with concerning frequency, often stemming from coolant leaks in water pumps and radiators. These cooling issues can rapidly escalate into more serious problems if left unaddressed. Overheating not only damages the engine directly but also exacerbates other existing problems within the powertrain. The resulting thermal stress accelerates wear on gaskets, seals, and metal components. Monitoring engine temperature gauges and addressing any fluctuations quickly helps prevent catastrophic engine failure. Coolant level checks should become part of regular maintenance routines for owners of vehicles equipped with this engine.

Transmission and Drivetrain Concerns

The Duramax 2.8L diesel engine paired with Allison transmissions faces exact transmission and drivetrain challenges that can significantly impact vehicle performance and reliability. These issues range from transmission limitations to component failures that often occur under high-stress conditions.

Torque Converter Issues

Torque converter problems represent a common complaint among Duramax 2.8L owners, manifesting as delayed engagement when shifting into Drive or Reverse. This delay places additional strain on transmission components, accelerating wear and potentially leading to premature failure. The root causes typically include low transmission fluid levels, worn-out torque converter components, or internal transmission faults that worsen over time. Early intervention when you notice hesitation during gear engagement prevents cascading damage throughout the transmission system. Many performance-oriented owners opt for upgraded multi-disc torque converters to enhance transmission durability and reduce slippage, especially in high-torque applications that push the stock components beyond their design limits.

Transmission Fluid Leaks

Transmission fluid leaks plague many Duramax trucks, particularly at connection points between transmission lines, the radiator, and the transmission itself. These vulnerable areas develop leaks due to extreme heat exposure that causes seals to deteriorate and lines to crack over time. Road debris impact, rust formation, ozone degradation, and contaminated fluid all contribute to the breakdown of transmission line integrity. The consequences of ignoring even minor leaks can be severe – from transmission overheating to complete transmission failure due to insufficient fluid levels. Your maintenance routine should include regular inspection of transmission lines, using the manufacturer-specified fluid type, and maintaining proper fluid levels to avoid these costly issues. Transmission line replacement becomes necessary once cracking or separation appears, as these conditions can rapidly worsen under normal driving conditions.

Performance and Power Delivery Problems

The 2.8L Duramax diesel engine exhibits several performance and power delivery issues that owners frequently encounter. These problems often manifest as poor idling, difficult starts, and unexpected check engine light activations. A failing purge valve solenoid is commonly identified as the root cause of these performance concerns.

Failing Purge Valve Solenoid

The purge valve solenoid failure in the 2.8L Duramax creates immediate drivability issues for many owners. Poor idling becomes noticeable when the engine struggles to maintain consistent RPMs at a standstill. Starting difficulties occur particularly in cold weather conditions, with the engine requiring multiple attempts before firing up. Check engine lights frequently illuminate due to this component failure, triggering diagnostic trouble codes related to evaporative emission control systems.

Oil Sludge Accumulation

Oil sludge buildup represents a important concern in the 2.8L Duramax engine’s overall performance. The engine generates considerable contaminants during normal operation, which can accumulate in the oil over time. This sludge directly affects critical components like cam journals and roller lifters, causing premature wear. More frequent oil changes than the manufacturer’s recommended intervals are necessary to mitigate this issue. Many owners report switching to synthetic oils and reducing their change intervals to 5,000 miles instead of the suggested 7,500 miles.

Injector Failures

Injector problems plague earlier models of the 2.8L Duramax engine with potentially catastrophic consequences. Stuck-open injectors allow excess fuel to enter the combustion chamber, resulting in melted pistons and extensive engine damage. This failure typically occurs without warning signs, leaving owners with sudden and complete engine failures. Replacement costs for damaged injectors and associated repairs often exceed $2,000, representing a important financial burden for affected owners.

Emissions System Complications

The emissions control systems in the 2.8L Duramax add layers of complexity that impact performance and reliability. The EGR system recirculates exhaust gases back into the combustion chamber but can become clogged with carbon deposits, restricting proper airflow. The diesel particulate filter (DPF) traps and removes soot from exhaust gases but requires periodic regeneration cycles that can interrupt normal driving patterns. The selective catalyst reduction system uses DEF (Diesel Exhaust Fluid) to reduce NOx emissions but adds another potential failure point to the engine’s operation.

Turbocharger Failures

Turbocharger issues in the 2.8L Duramax often stem from oil contamination and excessive wear on internal components. The variable geometry turbocharger design, while efficient for power delivery, contains moving parts susceptible to carbon buildup and sludge accumulation. Oil quality directly impacts turbocharger longevity, with contaminated oil accelerating bearing wear and reducing boost pressure over time. Symptoms of failing turbochargers include whistling noises, black exhaust smoke, and noticeable power reduction during acceleration.

Power Loss Concerns

Power loss in the 2.8L Duramax frequently results from internal engine damage affecting compression and combustion efficiency. Cracked or damaged pistons caused by injector failures reduce cylinder compression and diminish overall power output. Debris entering the cylinders through intake or oil circulation systems creates scoring on cylinder walls, further compromising engine performance. Several owners have reported sudden engine failures at mileages as low as 60,000-80,000 miles, requiring complete engine replacements costing $7,000-$9,000.

Emission control devices, while necessary for environmental compliance, inherently restrict exhaust flow and reduce potential power output. These systems create back pressure in the exhaust system that limits the engine’s ability to efficiently expel combustion gases. The restrictions imposed by catalytic converters, DPF systems, and exhaust gas recirculation components collectively contribute to decreased throttle response and diminished towing capacity compared to older, less regulated diesel engines.

Maintenance Tips to Prevent 2.8L Duramax Problems

Proper maintenance is crucial for extending the life of your 2.8L Duramax diesel engine and avoiding costly repairs. Following these exact maintenance practices helps address potential issues before they develop into major problems.

Regular Service Intervals

Frequent oil changes form the foundation of 2.8L Duramax reliability. The engine accumulates sludge and debris quickly due to its emissions system design, making regular oil maintenance essential for preventing internal damage. Schedule oil changes every 5,000-7,500 miles using manufacturer-recommended diesel-exact oil to maintain optimal engine performance. Inspecting and replacing air filters during these service intervals prevents contaminants from entering the engine system. Check and replace the fuel filter according to the maintenance schedule, as premature clogging is a common issue with these engines. Professional diagnostic scans during routine maintenance help catch error codes like P026D and P228C early, allowing you to address fuel system problems before they cause “Reduced Engine Power” warnings or engine stalling.

Quality Fuel and Additives

Using high-grade diesel fuel significantly reduces the risk of fuel system contamination in your 2.8L Duramax. Premium diesel contains fewer impurities that could potentially clog filters and damage sensitive fuel injectors. Add a quality diesel fuel treatment every 2-3 fill-ups to help clean injectors and prevent carbon buildup, especially important for maintaining the emission control systems. Fill up at high-volume stations where fuel turnover is frequent, ensuring fresher fuel with fewer contaminants that can accelerate filter clogging. During winter months, use winter-blend diesel or appropriate anti-gel additives to prevent fuel line freezing and starting issues. If experiencing persistent fuel-related problems, a complete system flush followed by filter replacement often resolves issues with contaminated fuel, restoring proper engine operation and preventing the recurring “Reduced Engine Power” warnings that frustrate many Duramax owners.

Cost Analysis of 2.8 Duramax Repairs

Fuel filter replacement for the 2.8 Duramax involves relatively low costs compared to other repairs, typically including parts and labor charges. Frequent replacements may be necessary due to early clogging issues, which increases your cumulative maintenance expenses over time. Using high-quality fuel can help extend filter life and reduce these recurring costs.

Fuel pump repairs represent a moderate to high expense when they fail in your Duramax. The combination of expensive parts and labor hours makes this a important repair consideration for owners experiencing starting problems or poor engine performance.

Transmission and torque converter issues rank among the most expensive repairs for 2.8 Duramax owners. Complex transmission work requires specialized knowledge and substantial labor time, with parts costs adding considerably to the final bill. Many owners report spending thousands on transmission-related repairs after experiencing shifting problems or converter failures.

Turbocharger repairs also command premium prices due to the sophisticated nature of these components. A failing turbo significantly impacts engine power and efficiency, making this a repair you can’t postpone even though the high cost. Replacement turbochargers plus installation labor typically run into four figures.

Injector failures present perhaps the most financially devastating scenario, especially in earlier engine versions. When injectors malfunction, they often cause pistons to melt or crack, leading to catastrophic engine damage. Complete engine rebuilds or replacements resulting from injector failures can cost several thousand dollars, making this the most expensive potential repair for your 2.8 Duramax.

Timing belt replacement falls into the moderate cost category but represents critical preventative maintenance. Neglecting this service interval can result in severe engine damage if the belt fails, turning a few hundred dollar maintenance item into a multi-thousand dollar engine repair.

Preventative maintenance costs, while regular expenses, eventually save you money by avoiding major repairs. Regular oil changes using proper diesel-exact oil help prevent the sludge buildup that contributes to overheating and accelerated engine wear. Investing in quality fuel and timely filter replacements also helps maintain fuel system integrity and prevent more expensive problems down the road.

Conclusion

The 2.8L Duramax delivers impressive torque and efficiency but comes with important challenges that you should anticipate. From DEF system failures to cooling issues and injector problems these complications can turn your powerful diesel into a costly headache.

By understanding these common problems you’ll be better equipped to catch warning signs early. Regular maintenance including timely oil changes proper filter replacements and quality fuel usage remains your best defense against major repairs.

While repair costs can be substantial especially for transmission and injector issues preventative care significantly reduces your long-term expenses. With proper attention and care your 2.8L Duramax can still deliver the performance and reliability you expect from this capable diesel engine.

Frequently Asked Questions

What are the most common issues with the 2.8L Duramax diesel engine?

The most common issues with the 2.8L Duramax diesel engine include DEF system failures, emission control problems (affecting the diesel oxidation catalyst, DPF, and EGR system), cooling system complications (such as coolant leaks from water pumps and radiators), fuel injector malfunctions, and transmission problems. These issues typically appear after 50,000-75,000 miles and can lead to reduced performance, engine power loss, or even complete breakdowns if not addressed promptly.

How much horsepower and torque does the 2.8L Duramax produce?

The 2.8L Duramax diesel engine produces 181 horsepower and 369 lb-ft of torque. This four-cylinder turbocharged engine was introduced in 2016 and designed to balance power with fuel efficiency for the North American market. Despite its smaller displacement, the substantial low-end torque allows for impressive towing capabilities in midsize trucks like the Chevrolet Colorado and GMC Canyon.

What is the towing capacity of vehicles with the 2.8L Duramax?

Vehicles equipped with the 2.8L Duramax diesel engine can tow up to 7,700 pounds. This impressive towing capacity for midsize trucks is primarily due to the engine’s substantial low-end torque of 369 lb-ft. The engine’s design, featuring a high-pressure common rail fuel system and variable geometry turbocharger, contributes to this capability while maintaining good fuel economy.

What causes the DEF system failures in the Duramax 2.8L?

DEF system failures in the 2.8L Duramax typically stem from issues with the Selective Catalytic Reduction (SCR) system components. These include sensor malfunctions, DEF injector clogs, DEF pump failures, or DEF fluid quality problems. Many owners report warning messages after 50,000-75,000 miles. These failures can trigger check engine lights and potentially limit vehicle speed if not addressed, as they’re part of the emissions control system required for EPA compliance.

How often should I change the oil in my 2.8L Duramax?

Oil changes for the 2.8L Duramax diesel engine should be performed every 5,000-7,500 miles. Using manufacturer-recommended diesel-specific oil is crucial to prevent sludge buildup, which can damage critical engine components. More frequent changes may be necessary for vehicles operated in severe conditions such as extreme temperatures, frequent short trips, or heavy towing. Regular oil maintenance is one of the most effective ways to extend engine life.

What are signs of injector failure in the 2.8L Duramax?

Signs of injector failure in the 2.8L Duramax include rough idling, difficulty starting, significant power loss, excessive smoke from the exhaust, poor fuel economy, and engine misfires. You might also notice unusual knocking sounds or the check engine light illuminating. Early detection is critical, as injector failures can lead to catastrophic engine damage if left unaddressed, potentially resulting in expensive repairs or even complete engine rebuilds.

How can I prevent cooling system problems in my Duramax 2.8L?

Prevent cooling system problems by regularly inspecting for coolant leaks, maintaining proper coolant levels with the recommended fluid type, and replacing the water pump preventatively around 60,000-80,000 miles. Have the radiator and cooling system professionally flushed every 30,000-50,000 miles to remove contaminants. Also, monitor temperature gauges while driving and address any overheating immediately to prevent extensive engine damage.

What is causing transmission issues in vehicles with the 2.8L Duramax?

Transmission issues in 2.8L Duramax vehicles often stem from torque converter problems causing delayed gear engagement and fluid leaks at connection points. Contributing factors include heat exposure, road debris impact, and wear on gaskets and seals. The high torque output can stress transmission components, particularly when frequently towing. Regular transmission fluid checks, prompt repair of leaks, and avoiding aggressive driving can help prevent these costly problems.

How expensive are repairs for the 2.8L Duramax diesel engine?

Repair costs for the 2.8L Duramax vary widely: fuel filter replacements are relatively inexpensive ($50-150), fuel pump repairs moderate ($500-1,000), while transmission and torque converter repairs are very expensive ($2,000-4,000). Turbocharger repairs typically cost $1,500-2,500. The most costly repairs involve injector failures or engine rebuilds, which can exceed $5,000-8,000. Preventative maintenance, while a regular expense, ultimately saves money by avoiding these major repairs.

What maintenance tips can extend the life of my 2.8L Duramax engine?

To extend your 2.8L Duramax’s life, follow these key practices: change oil every 5,000-7,500 miles using diesel-specific oil; replace air and fuel filters regularly; use high-quality diesel fuel and consider fuel additives to reduce contamination; schedule professional diagnostic scans to catch issues early; monitor and promptly address warning lights; and maintain the cooling system properly. Following manufacturer-recommended service intervals and addressing small problems before they escalate will significantly improve long-term reliability.