Are you experiencing frustrating issues with your 6.6 Duramax diesel engine? While these powerhouses are known for their impressive performance and longevity, they’re not without their share of common problems that can leave owners scratching their heads.

The 6.6 Duramax has powered GM’s heavy-duty trucks since 2001, earning a reputation for reliability. But, certain model years have developed notorious issues including fuel system failures, emissions equipment malfunctions, and cooling system complications. Understanding these potential problems before they escalate can save you thousands in repair costs and prevent unexpected breakdowns when you need your truck most.

Common 6.6 Duramax Diesel Engine Problems

The 6.6 Duramax diesel engine has earned its reputation as a powerhouse in GM’s heavy-duty truck lineup, but several recurring issues plague exact generations. Many owners experience these problems across different model years, with varying severity depending on maintenance history and operating conditions.

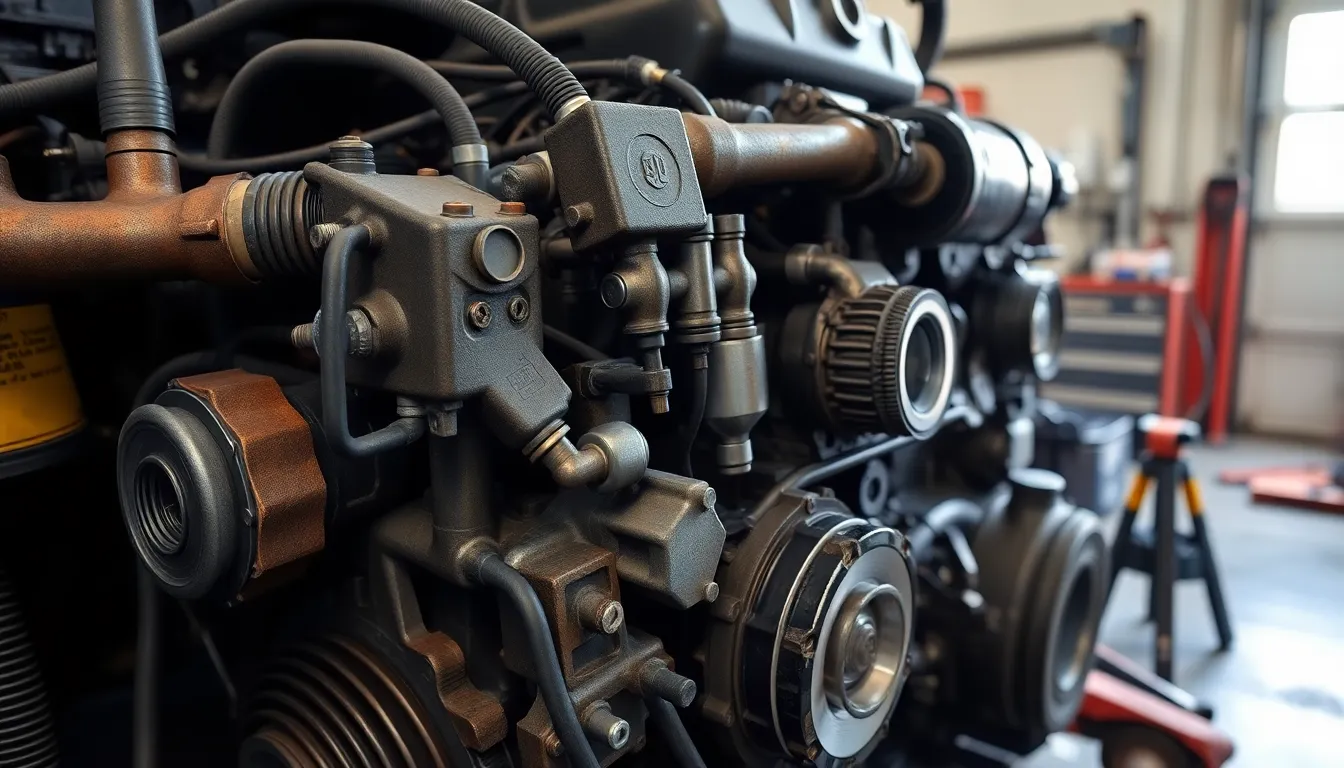

Fuel System Failures

Fuel system components represent the most frequent failure points in Duramax engines, particularly in LB7 (2001-2004) models. Injector failures occur commonly in these early versions, with symptoms including rough idling, excessive smoke, hard starting, and reduced power. Replacement costs for a complete set of injectors range from $3,000 to $5,000 including labor.

CP3 injection pumps in LBZ and LMM models (2006-2010) often fail due to contaminated fuel or normal wear. Signs of pump failure include loss of power, engine hesitation, and inability to maintain speed under load. Dirty fuel filters accelerate this deterioration, making regular filter changes essential for prevention.

Emissions System Problems

Exhaust Gas Recirculation (EGR) systems frequently clog with soot in LLY and LBZ models (2004-2007). Carbon buildup restricts exhaust flow, causing overheating issues and reduced performance. Cleaning or replacing the EGR cooler and valve costs approximately $1,200-2,500 depending on the extent of damage.

Diesel Particulate Filters (DPF) in LMM and LML generations (2007-2016) often clog prematurely, especially with frequent short trips that prevent regeneration cycles from completing. Symptoms include increased fuel consumption, reduced power, and dashboard warning lights. Complete DPF replacement costs range from $2,000 to $4,000 at dealerships.

Cooling System Issues

Head gasket failures plague LB7 and LLY models (2001-2005) due to inadequate cooling system design. Overheating under heavy loads causes coolant leaks, white exhaust smoke, and coolant-oil mixing. Complete repair with upgraded components costs $3,500-5,000 and requires extensive labor.

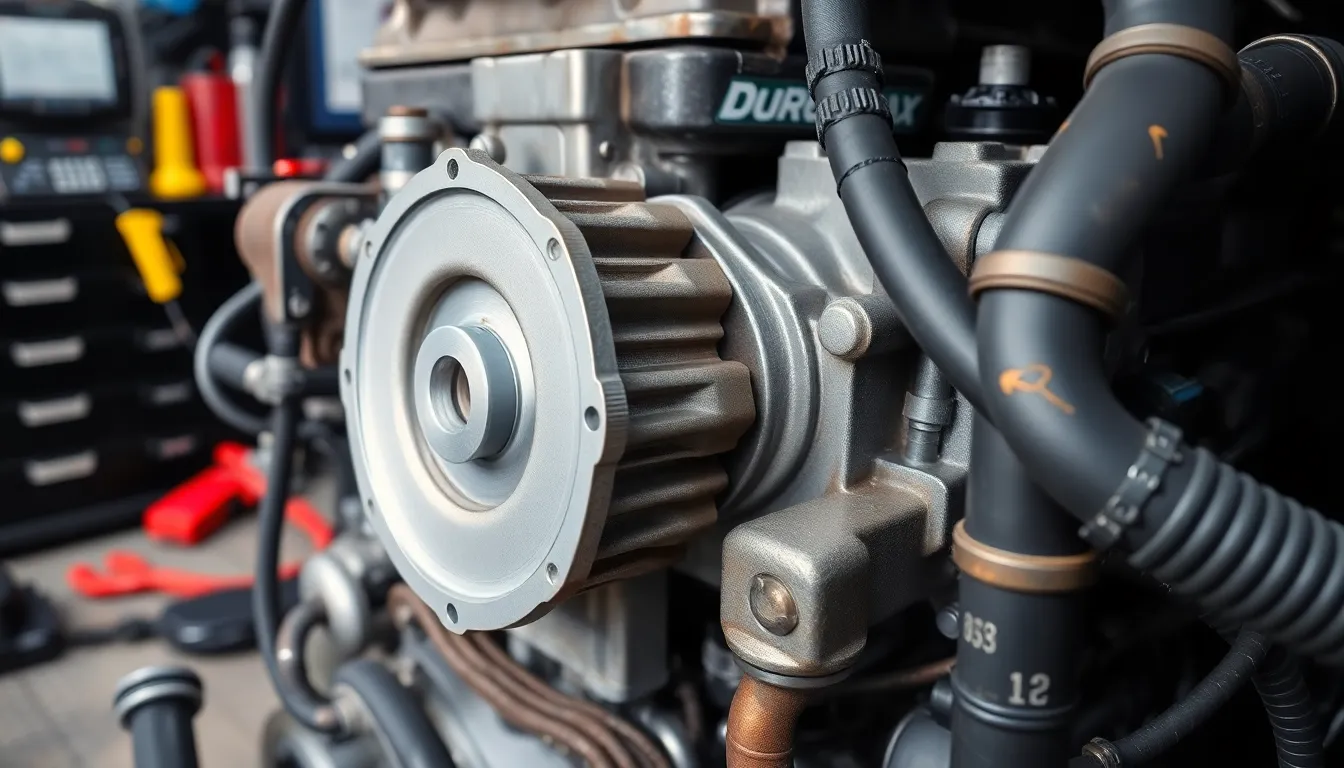

Water pump failures occur frequently after 80,000-100,000 miles in most Duramax generations. Leaking coolant from the weep hole indicates imminent failure, requiring prompt replacement to prevent engine overheating. Replacement parts and labor typically cost $600-900 at specialized diesel shops.

Glow Plug System Failures

Glow plug issues commonly affect LB7 through LMM models (2001-2010), causing hard starting in cold weather. Controller failures can trigger check engine lights and prevent proper pre-heating of the combustion chambers. Complete system replacement, including controller and plugs, costs approximately $800-1,200.

Later LML models (2011-2016) use improved glow plug designs but still experience controller failures. Replacement plugs for these generations are more expensive but generally more reliable than their predecessors.

Turbocharger Problems

Turbocharger failures frequently occur in LB7 and LLY models (2001-2005) after 150,000 miles. Bearing wear causes oil leaks, excessive smoke, and distinctive whistling noises during acceleration. Replacement turbochargers cost $1,500-2,500 installed.

Variable geometry turbochargers in LMM and later models (2007-present) experience actuator failures and carbon buildup that restrict vane movement. Symptoms include reduced boost pressure, poor acceleration, and intermittent power loss.

Transmission Issues

Allison 1000 transmissions paired with Duramax engines commonly develop torque converter clutch slippage after 100,000 miles, especially in trucks used for heavy towing. Transmission fluid overheating accelerates wear on clutch materials. Rebuilt transmissions with upgraded components cost $3,500-5,000 installed.

Valve body issues in 2006-2010 models create erratic shifting patterns and delayed engagement. These problems worsen gradually, eventually requiring complete transmission rebuilds if not addressed early.

Fuel System Issues

Fuel system problems plague many 6.6 Duramax diesel engines across multiple generations, causing important performance issues and unexpected breakdowns. These problems stem from the engine’s unique design using an injection pump instead of a lift pump, creating vulnerabilities in the fuel delivery system.

Injector Failure

Injectors in the 6.6L Duramax frequently fail, leading to costly repairs and frustrating performance problems. Symptoms of injector failure include misfiring engines, power loss, excessive smoke emissions, hard starting, and rough running conditions. The issue is particularly common in LB7 models (2001-2004), where injector harness chafing creates electrical problems that compound the mechanical failures. Many truck owners report experiencing these problems between 80,000-120,000 miles, forcing them to replace multiple injectors at once. Complete fuel injector replacement kits can cost $2,500-$4,000 depending on the model year and labor rates at your service center.

Fuel Pressure Regulator Problems

Fuel pressure regulator malfunctions create erratic engine performance and contribute to premature component wear throughout the fuel system. The regulator’s role in maintaining consistent fuel pressure becomes compromised due to clogging, carbon buildup, or mechanical failure. These issues often manifest as hesitation during acceleration, power fluctuations, and unpredictable engine behavior. The Bosch CP4 high-pressure fuel pump, operating at extremely high pressures, represents the most catastrophic failure point in the Duramax fuel system. This pump can suddenly fail while driving, causing immediate engine shutdown and leaving you stranded. The failure typically contaminates the entire fuel system with metal particles, requiring comprehensive fuel system repairs that can exceed $8,000. Truck owners frequently describe these failures as happening without warning signs, making preventative maintenance critical for protecting your Duramax diesel.

EGR System Troubles

The Exhaust Gas Recirculation (EGR) system in the 6.6 Duramax diesel engine presents many challenges for truck owners. This emissions control component frequently develops problems that can significantly impact engine performance and longevity.

EGR Valve Clogging

Carbon buildup inside the EGR valve ranks among the most prevalent issues affecting 6.6 Duramax diesel engines. Excessive smoke, sudden power loss, and poor engine performance often indicate a clogged EGR valve. These carbon deposits gradually restrict the valve’s functionality, preventing your truck from accelerating properly and reducing fuel efficiency. Models with the LML version (2011-2016) experience this problem with notable frequency. Many Duramax owners report frustration with the recurring nature of this issue, as normal driving conditions inevitably lead to carbon accumulation within the EGR system.

EGR Cooler Failure

EGR cooler failures represent another critical weakness in the 6.6 Duramax diesel engine. This component cools exhaust gases before recirculating them back into the engine, but frequently succumbs to the constant heat stress and soot exposure. When an EGR cooler fails, your engine faces risks of overheating and potentially catastrophic damage. The combination of high operating temperatures and carbon-laden exhaust creates an extremely harsh environment for the cooler, drastically reducing its operational lifespan. Though less specifically documented than valve clogging, cooler failure remains a consistent concern for Duramax owners who’ve experienced the substantial repair costs associated with this component’s breakdown.

Head Gasket Failures

Head gasket failures rank among the most common problems plaguing the 6.6 Duramax diesel engine. Overheating stands as the primary culprit behind these failures, as head gaskets constantly endure extreme temperature fluctuations and pressure changes that wear them down over time. Different Duramax generations feature various gasket designs, yet all remain vulnerable to heat-related damage.

Unlike some engine components with predictable lifespans, head gaskets don’t follow a definitive failure timeline. They’re typically one of the first major engine parts to fail in a Duramax diesel, making this an anticipated maintenance issue throughout your truck’s life.

Several telltale signs indicate a blown head gasket:

- Coolant leaks appearing around the engine

- White smoke billowing from your exhaust (from burning coolant)

- Sweet-smelling exhaust fumes

- Milky oil indicating coolant-oil intermixing

- Pressure buildup in the cooling system

- Unexplained coolant loss

- Engine overheating

- Coolant puddles forming under your parked truck

The multi-layer metal head gaskets in Duramax engines prevent catastrophic failures but aren’t immune to problems. When these gaskets weaken, combustion gases can seep between layers, pressurizing the cooling system and forcing coolant out. This gradual degradation often leads to complete failure if not addressed promptly.

Repairs require removing the cylinder head and replacing the gasket with careful attention to proper torque specifications. Mechanics need exact tools, including a 17mm 12-point shallow socket, to ensure even clamping force during reassembly. Early production LBZ Duramax engines (2006) feature a different gasket design that proved particularly susceptible to failures, making these models more prone to this issue.

Regular cooling system maintenance and avoiding engine overheating represent your best defense against costly head gasket repairs. Monitoring coolant levels and addressing temperature spikes immediately can significantly extend your head gasket’s lifespan.

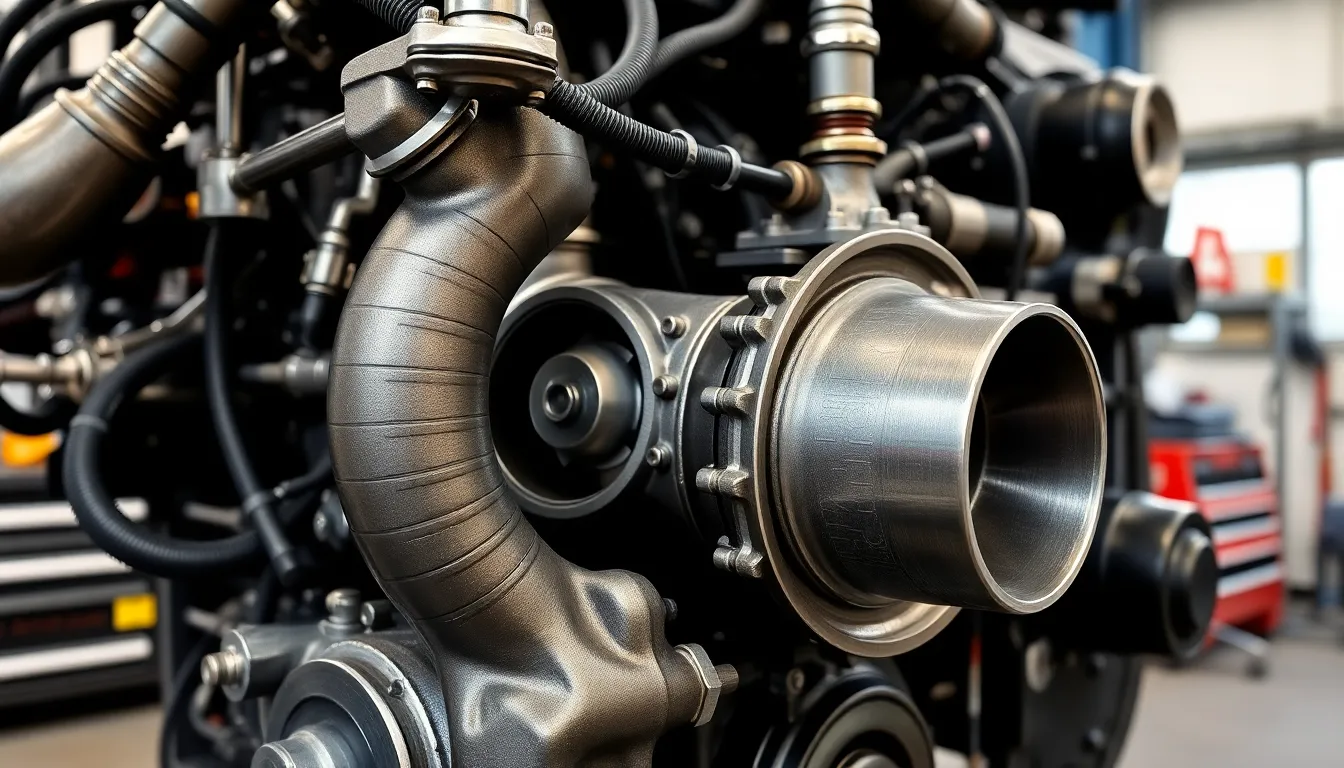

Turbocharger Problems

The 6.6L Duramax diesel engine faces several important turbocharger-related issues that can severely impact performance and longevity. Turbocharger oil leaks represent one of the most common problems, often stemming from a faulty Positive Crankcase Ventilation (PCV) system design that allows engine oil to infiltrate the turbocharger components.

Variable Geometry Turbo Failures

Variable geometry turbocharger (VGT) systems in the 6.6L Duramax commonly experience both mechanical failures and sensor issues. These sophisticated turbo systems frequently throw error codes like P0046 and P2563, particularly noticeable in 2005 LLY Duramax models. The intermittent nature of VGT malfunctions creates diagnostic challenges, often requiring specialized equipment to properly identify the root cause. When the VGT system fails, inconsistent boost delivery becomes apparent, resulting in sluggish acceleration, reduced power output, and poor overall engine performance. Many Duramax owners report frustration with the variable geometry mechanisms that can stick or seize due to carbon buildup and soot accumulation over time.

Boost Pressure Issues

Boost pressure problems in the Duramax typically manifest as decreased engine power and noticeable performance degradation during acceleration or hauling. Faulty turbo components, malfunctioning wastegates, and oil ingestion into the turbo can all contribute to reduced boost pressure in these engines. The Duramax’s unique fuel delivery system complicates matters further, as it lacks a traditional lift pump and instead relies on the injection pump. Cracks or air leaks in the fuel filter housing frequently lead to both boost pressure and fuel delivery issues. Many owners experience intermittent power loss when driving uphill or towing heavy loads, a telltale sign of boost pressure problems. Regular inspection of turbo components, boost sensors, and associated hoses can help identify potential issues before they cause catastrophic engine damage or leave you stranded during critical hauling operations.

Cooling System Complications

The 6.6 Duramax diesel engine frequently experiences cooling system issues that can lead to important engine damage if left unaddressed. Low coolant levels represent one of the most common problems, often resulting from external leaks in various components. Air trapped in the cooling system due to improper filling procedures typically triggers low coolant warnings and overheating episodes. Faulty radiator caps and damaged cylinder head gaskets contribute to coolant loss and pressure problems, requiring thorough inspection and pressure testing for accurate diagnosis.

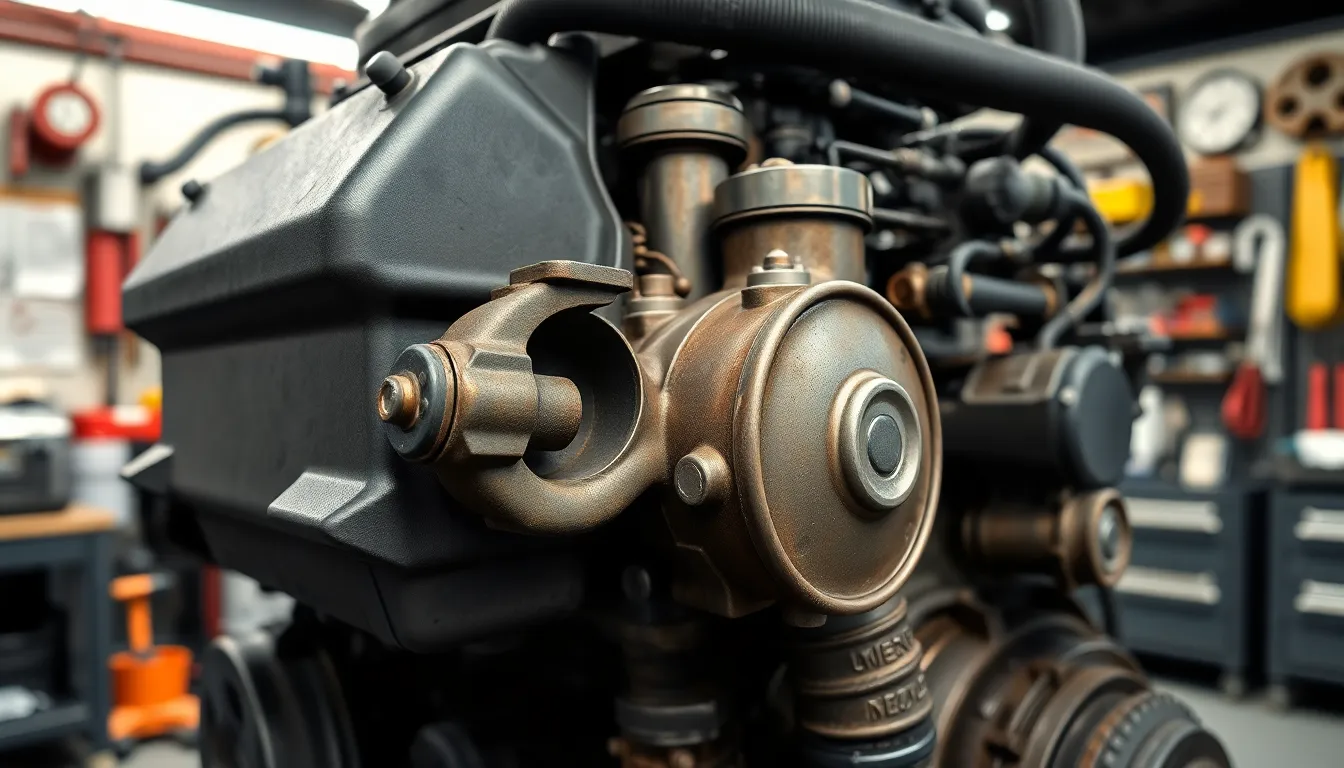

Water Pump Failures

Water pump malfunctions in 6.6 Duramax engines often stem from their plastic impeller design, especially in newer models. These plastic impellers commonly spin on the driveshaft, drastically reducing coolant flow and causing engine overheating. External leaks from water pumps lead to coolant pressure loss, compromising the entire cooling system’s efficiency. Upgrading to a water pump with a metal impeller provides a reliable solution to prevent recurring issues. Early detection of water pump problems is essential, as catching these failures before they progress can save you thousands in repair costs and prevent catastrophic engine damage.

Radiator Leaks

Radiator core and hose leaks plague many 6.6 Duramax diesel engines, resulting in coolant loss and potential engine overheating. Fan clutch failures, particularly common in 2005 and earlier models, significantly reduce airflow through the radiator, worsening existing cooling problems. The fan clutch works along with the water pump to maintain proper radiator airflow, creating a critical cooling system dependency. Damaged radiator components often manifest as coolant puddles under your truck or visible leaks around hose connections. Regular inspections of radiator components can help identify small leaks before they develop into major problems, saving you considerable time and expense on repairs.

Transmission Concerns with Duramax Engines

The Allison 1000 transmission paired with the 6.6L Duramax diesel engine experiences several recurring issues that can impact performance and reliability. While respected for its smooth shifting and ability to handle diesel torque, this transmission system has exact vulnerabilities owners should recognize.

Input Shaft Failures

Input shaft problems are particularly common in 2011 and newer LML and L5P Duramax models. These shafts incorporate an internal oil circuit that reduces steel volume, making them vulnerable to failure under heavy towing conditions or when power exceeds approximately 550 horsepower. Many owners find upgrading to a CNC machined billet steel input shaft provides essential durability for high-power applications or regular towing.

Power Limitations and Limp Mode

Transmission power handling varies significantly across Duramax generations. Five-speed Allison transmissions (used through 2005) represent the weakest link, frequently entering limp mode or triggering reduced engine power warnings when pushed beyond 400 horsepower due to clutch slippage. Six-speed Allison units (2006-2019) offer improved mechanical strength but still benefit from aftermarket modifications. These transmissions can handle up to 500 horsepower with appropriate upgrades like shift kits and enhanced friction materials, with 2011 and later models demonstrating the greatest strength.

Fluid Leaks and Cooling Issues

Transmission fluid leaks present a persistent concern, especially in newer 2024-2025 Duramax trucks where owners report leakage at surprisingly low mileage. These leaks typically stem from deteriorated transmission cooler lines or connection points and require prompt attention to prevent more severe transmission damage. Adequate cooling remains critical for transmission longevity in these high-torque applications.

Diagnostic Challenges

The Transmission Control Module (TCM) often triggers limp mode as a protective measure when detecting slippage or internal faults, restricting the vehicle to third gear operation. Diagnostic code P0700 frequently appears during these episodes, indicating a transmission-related problem that requires further investigation to pinpoint the exact cause. This protective limitation significantly impacts drivability until properly addressed.

Durability Considerations

Even though its reputation for reliability, the Allison 1000 transmission demands respect for its operational limits. Aggressive driving habits, excessive power modifications without supporting transmission upgrades, and extreme towing conditions without proper cooling can all lead to premature failure. Preventative upgrades including improved friction materials, hydraulic modifications, enhanced torque converters, and supplemental cooling systems help extend transmission life while preventing frustrating limp mode occurrences during critical use.

Conclusion

Owning a 6.6 Duramax diesel engine means having impressive power and longevity but also facing potential challenges. By familiarizing yourself with these common problems you’ll be better equipped to detect issues early and prevent costly repairs down the road.

Regular maintenance is your best defense against many of these problems. Pay special attention to your fuel system cooling components and emissions equipment as these are the most vulnerable areas.

Remember that different model years have their own exact weaknesses. Whether you’re dealing with injector failures in the LB7 or DPF issues in the LML knowing what to watch for will help you maximize your Duramax’s performance and lifespan.

Frequently Asked Questions

What are the most common issues with the 6.6 Duramax diesel engine?

The most common issues include fuel system failures (especially in LB7 models), emissions equipment malfunctions (EGR and DPF problems), cooling system complications (head gasket and water pump failures), glow plug system failures, turbocharger problems, and transmission issues with the Allison 1000. Specific model years have their own typical problems, with earlier generations (2001-2010) experiencing more frequent fuel and turbo issues.

Which Duramax model years should I avoid?

The LB7 models (2001-2004) are known for frequent injector failures, while LBZ and LMM models (2006-2010) commonly experience CP3 pump issues. The LMM and LML generations (2007-2016) often have premature DPF clogging. If reliability is your priority, the newer L5P models (2017+) have addressed many previous issues, while the LBZ (2006-2007) is often considered the most reliable of the older generations.

How can I identify fuel injector problems in my Duramax?

Look for symptoms including rough idling, engine misfires, significant power loss, excessive smoke from the exhaust (particularly white or black), poor fuel economy, and hard starting. You may also notice a knocking sound or diesel knock that’s louder than normal. Early diagnosis can prevent more extensive damage and reduce repair costs, especially in LB7 models where injector replacement is common.

What causes head gasket failures in Duramax engines?

Head gasket failures are primarily caused by engine overheating, which can result from cooling system issues, extreme towing conditions, or engine modifications that increase heat. The multi-layer metal head gaskets in Duramax engines can weaken over time. Signs include coolant leaks, white smoke from the exhaust, milky oil, and engine overheating. Regular cooling system maintenance and avoiding prolonged heavy loads can help prevent failures.

How often should I replace the fuel filter on my Duramax?

You should replace the fuel filter every 10,000-15,000 miles under normal driving conditions. If you frequently drive in dusty environments, tow heavy loads, or use lower quality diesel fuel, consider changing it more often (every 7,500-10,000 miles). Regular fuel filter changes are one of the most cost-effective ways to prevent expensive fuel system repairs and maintain optimal engine performance.

What are signs of turbocharger failure in a Duramax?

Signs include excessive black smoke from the exhaust, decreased engine power (especially during acceleration), unusual whistling or shrieking noises, increased oil consumption, oil leaks around the turbo area, and check engine lights related to boost pressure. Variable geometry turbocharger (VGT) failures are common in LB7 and LLY models (2001-2005) and often present as poor throttle response or laggy acceleration.

How reliable is the Allison 1000 transmission paired with Duramax engines?

The Allison 1000 transmission is generally very reliable when properly maintained, but can experience issues after 100,000 miles, particularly torque converter clutch slippage. Input shaft failures are more common in LML and L5P models. The transmission may enter limp mode when pushed beyond power limitations. Regular transmission fluid and filter changes every 50,000 miles can significantly extend transmission life.

What maintenance can prevent EGR system failures?

Regular cleaning of the EGR valve and cooler every 50,000-75,000 miles can prevent clogging. Using high-quality diesel fuel and engine oil designed for modern diesel engines helps reduce carbon buildup. Consider an EGR delete if legally permitted in your area. Monitor for symptoms like excessive smoke, rough idle, and power loss. Most importantly, address check engine lights promptly to prevent more serious damage.

How can I improve the longevity of my Duramax cooling system?

Regularly inspect for leaks and maintain proper coolant levels with the manufacturer-recommended coolant. Replace the water pump preventatively around 100,000 miles, considering an upgrade from plastic to metal impellers for better reliability. Flush the cooling system every 60,000-100,000 miles. Monitor temperatures carefully when towing or during high-load situations. Address radiator issues promptly to prevent overheating.

Is the CP4 high-pressure fuel pump reliable in Duramax engines?

The Bosch CP4 pump used in LML models (2011-2016) is known for catastrophic failures. These failures often occur without warning and can contaminate the entire fuel system with metal particles, leading to expensive repairs. Installing a lift pump system to ensure adequate fuel supply and pressure can help prevent failures. Using high-quality diesel fuel with proper lubricity and changing fuel filters regularly also improves reliability.